Boiler house

Steam injectors

Local regulations may restrict the use of this product to below the conditions quoted.

In the interests of development and improvement of the product, we reserve the right to change the specification without notice. © Copyright 2014

2.2.3

TI-P401-04

AB Issue 3

INS6 and INS10

Direct Steam Injection Heating Systems

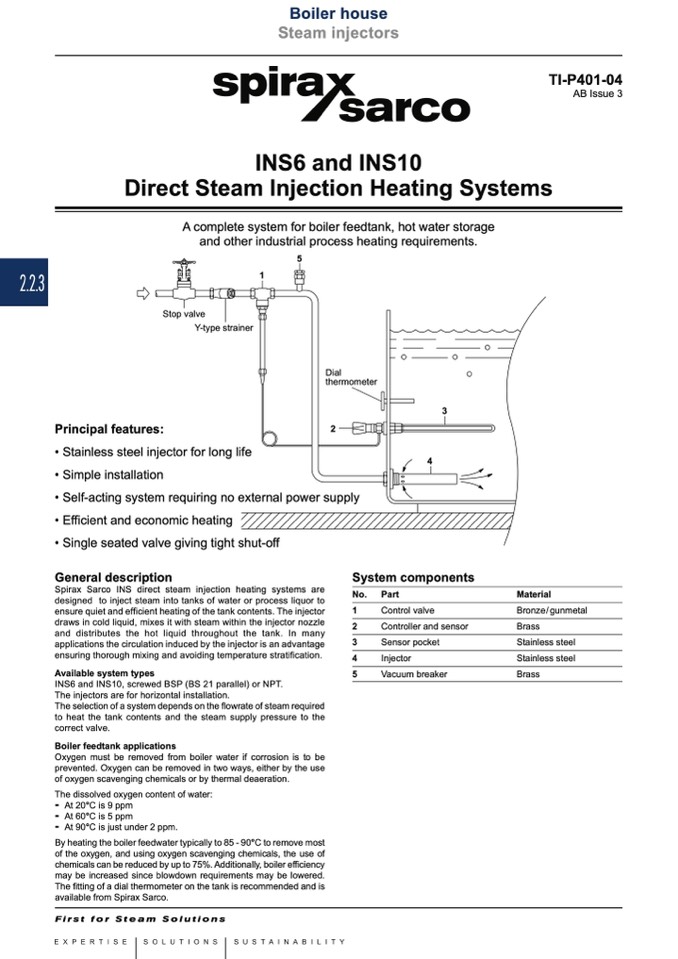

A complete system for boiler feedtank, hot water storage

and other industrial process heating requirements.

5

1

Stop valve

Y-type strainer

Principal features:

Dial

thermometer

2

3

4

• Stainless steel injector for long life

• Simple installation

• Self-acting system requiring no external power supply

• Efficient and economic heating

• Single seated valve giving tight shut-off

General description

Spirax Sarco INS direct steam injection heating systems are

designed to inject steam into tanks of water or process liquor to

ensure quiet and efficient heating of the tank contents. The injector

draws in cold liquid, mixes it with steam within the injector nozzle

and distributes the hot liquid throughout the tank. In many

applications the circulation induced by the injector is an advantage

ensuring thorough mixing and avoiding temperature stratification.

Available system types

INS6 and INS10, screwed BSP (BS 21 parallel) or NPT.

The injectors are for horizontal installation.

The selection of a system depends on the flowrate of steam required

to heat the tank contents and the steam supply pressure to the

correct valve.

Boiler feedtank applications

Oxygen must be removed from boiler water if corrosion is to be

prevented. Oxygen can be removed in two ways, either by the use

of oxygen scavenging chemicals or by thermal deaeration.

The dissolved oxygen content of water:

-

At 20°C is 9 ppm

-

At 60°C is 5 ppm

-

At 90°C is just under 2 ppm.

By heating the boiler feedwater typically to 85 - 90°C to remove most

of the oxygen, and using oxygen scavenging chemicals, the use of

chemicals can be reduced by up to 75%. Additionally, boiler efficiency

may be increased since blowdown requirements may be lowered.

The fitting of a dial thermometer on the tank is recommended and is

available from Spirax Sarco.

System components

No. Part

1

Control valve

2

Controller and sensor

3

Sensor pocket

4

Injector

5

Vacuum breaker

Material

Bronze / gunmetal

Brass

Stainless steel

Stainless steel

Brass