Boiler house

Steam injectors

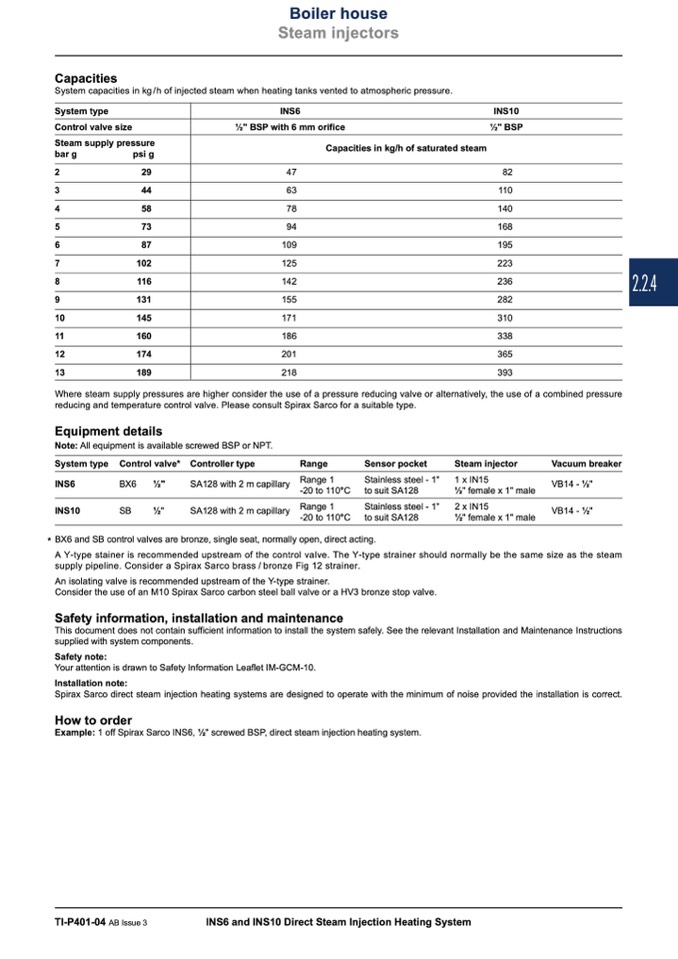

Capacities

System capacities in kg/h of injected steam when heating tanks vented to atmospheric pressure.

System type

Control valve size

Steam supply pressure

INS6

1⁄2" BSP with 6 mm orifice

INS10

1⁄2" BSP

82

110

140

168

195

223

236

282

310

338

365

393

bar g

2

3

4

5

6

7

8

9

10

11

12

13

psi g

29

47

44

63

58

78

73

94

87

109

102

125

116

142

131

155

145

171

160

186

174

201

189

218

Capacities in kg/h of saturated steam

Where steam supply pressures are higher consider the use of a pressure reducing valve or alternatively, the use of a combined pressure

reducing and temperature control valve. Please consult Spirax Sarco for a suitable type.

Equipment details

Note: All equipment is available screwed BSP or NPT.

System type Control valve*

INS6

BX6

1⁄2"

INS10

SB

1⁄2"

* BX6 and SB control valves are bronze, single seat, normally open, direct acting.

supply pipeline. Consider a Spirax Sarco brass / bronze Fig 12 strainer.

An isolating valve is recommended upstream of the Y-type strainer.

Consider the use of an M10 Spirax Sarco carbon steel ball valve or a HV3 bronze stop valve.

Safety information, installation and maintenance

This document does not contain sufficient information to install the system safely. See the relevant Installation and Maintenance Instructions

supplied with system components.

Safety note:

Your attention is drawn to Safety Information Leaflet IM-GCM-10.

Installation note:

Spirax Sarco direct steam injection heating systems are designed to operate with the minimum of noise provided the installation is correct.

How to order

Example: 1 off Spirax Sarco INS6, 1⁄2" screwed BSP, direct steam injection heating system.

Controller type

SA128 with 2 m capillary

Range

Range 1

-20 to 110°C

Sensor pocket

Stainless steel - 1"

to suit SA128

Steam injector

1 x IN15

1⁄2" female x 1" male

Vacuum breaker

VB14 - 1⁄2"

Range 1

-20 to 110°C

Stainless steel - 1"

to suit SA128

2 x IN15

1⁄2" female x 1" male

VB14 - 1⁄2"

A Y-type stainer is recommended upstream of the control valve. The Y-type strainer should normally be the same size as the steam

SA128 with 2 m capillary

TI-P401-04 AB Issue 3

INS6 and INS10 Direct Steam Injection Heating System

2.2.4