Boiler house

Steam injectors

Safety information, installation and maintenance

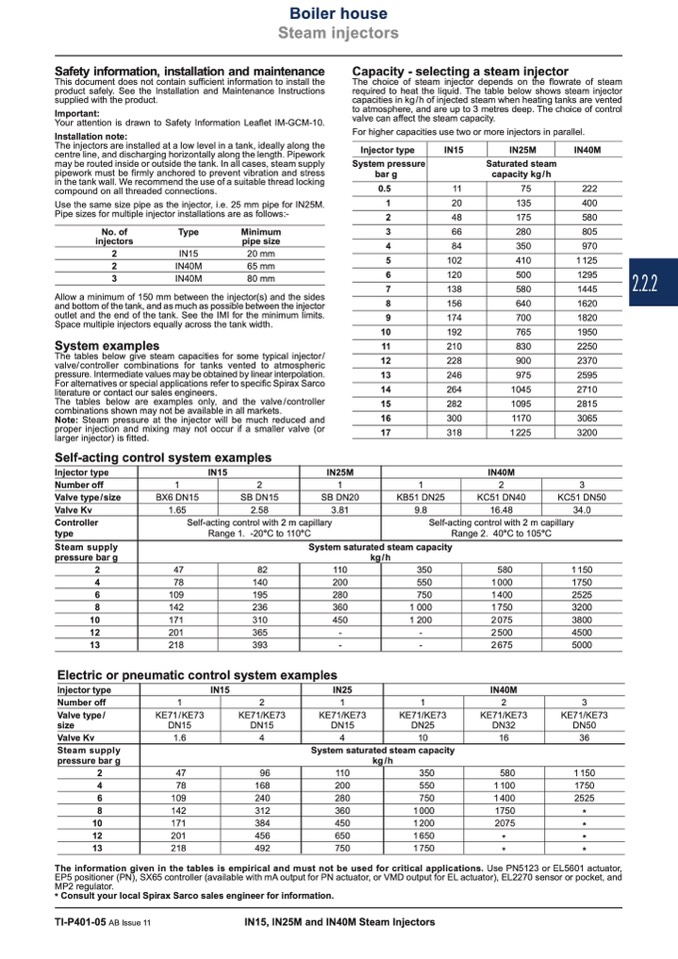

Capacity - selecting a steam injector

This document does not contain sufficient information to install the

product safely. See the Installation and Maintenance Instructions

supplied with the product.

The choice of steam injector depends on the flowrate of steam

required to heat the liquid. The table below shows steam injector

capacities in kg / h of injected steam when heating tanks are vented

to atmosphere, and are up to 3 metres deep. The choice of control

valve can affect the steam capacity.

Important:

Your attention is drawn to Safety Information Leaflet IM-GCM-10.

Installation note:

The injectors are installed at a low level in a tank, ideally along the

centre line, and discharging horizontally along the length. Pipework

may be routed inside or outside the tank. In all cases, steam supply

pipework must be firmly anchored to prevent vibration and stress

in the tank wall. We recommend the use of a suitable thread locking

compound on all threaded connections.

Use the same size pipe as the injector, i.e. 25 mm pipe for IN25M.

Pipe sizes for multiple injector installations are as follows:-

For higher capacities use two or more injectors in parallel.

IN15 IN25M

1

BX6 DN15

1.65

1

KE71 / KE73

DN15

1.6

IN15

IN15

2

SB DN15

2.58

Self-acting control with 2 m capillary

Range 1. -20°C to 110°C

2

KE71/KE73

DN15

4

IN25M

1

SB DN20

3.81

Injector type

System pressure

bar g

0.5

1

2

3

4

Saturated steam

capacity kg/h

IN40M

222

400

580

805

970

11

75

20

135

48

175

66

280

84

350

102

410

120

500

138

580

156

640

174

700

192

765

210

830

228

900

246

975

264

1045

282

1095

300

1170

318

1 225

No. of

Type

injectors

2

IN15

2

IN40M

3

IN40M

Minimum

pipe size

20 mm

65 mm

80 mm

5

1125

6

1295

7

1445

8

1620

9

1820

10

1950

11

2250

12

2370

13

2595

14

2710

15

2815

16

3065

17

3200

Allow a minimum of 150 mm between the injector(s) and the sides

and bottom of the tank, and as much as possible between the injector

outlet and the end of the tank. See the IMI for the minimum limits.

Space multiple injectors equally across the tank width.

The tables below give steam capacities for some typical injector/

valve/controller combinations for tanks vented to atmospheric

pressure. Intermediate values may be obtained by linear interpolation.

For alternatives or special applications refer to specific Spirax Sarco

literature or contact our sales engineers.

Self-acting control system examples

Injector type

Number off

Valve type/size

Valve Kv

Controller

type

Steam supply

pressure bar g

System examples

The tables below are examples only, and the valve/controller

combinations shown may not be available in all markets.

Note: Steam pressure at the injector will be much reduced and

proper injection and mixing may not occur if a smaller valve (or

larger injector) is fitted.

IN40M

3

KC51 DN50

34.0

Self-acting control with 2 m capillary

Range 2. 40°C to 105°C

System saturated steam capacity

kg/h

47

82

110

350

580

78

140

200

550

1 000

109

195

280

750

1 400

142

236

360

1 000

1 750

171

310

450

1 200

2 075

201

365

-

-

2 500

218

393

-

-

2 675

2

1150

4

1750

6

2525

8

3200

10

3800

12

4500

13

5000

Electric or pneumatic control system examples

Injector type

Number off

Valve type/

IN40M

3

KE71/KE73

DN50

36

IN25

1

size

Valve Kv

Steam supply

pressure bar g

System saturated steam capacity

kg/h

KE71/KE73

DN15

4

1

KB51 DN25

9.8

1

KE71/KE73

DN25

10

2

KC51 DN40

16.48

2

KE71/KE73

DN32

16

47

96

110

350

580

78

168

200

550

1 100

109

240

280

750

1 400

142

312

360

1 000

1750

171

384

450

1 200

2075

201

456

650

1 650

*

218

492

750

1 750

*

2

1150

4

1750

6

2525

8

10

12

13

*

*

*

*

The information given in the tables is empirical and must not be used for critical applications. Use PN5123 or EL5601 actuator,

EP5 positioner (PN), SX65 controller (available with mA output for PN actuator, or VMD output for EL actuator), EL2270 sensor or pocket, and

MP2 regulator.

* Consult your local Spirax Sarco sales engineer for information.

TI-P401-05 AB Issue 11

IN15, IN25M and IN40M Steam Injectors

2.2.2