Boiler house

Feedtank ancillaries

Materials

No. Description

1

Arm body

2

Protector rods

3

Glass tube

4

Gland nut

5

Top plug

6

Plug cock

7

Packing sleeve

8

Packing washer

9

Top plug gasket

10 'C' section protector

11 Plastic tube

12 Tube supports

(used with item 11)

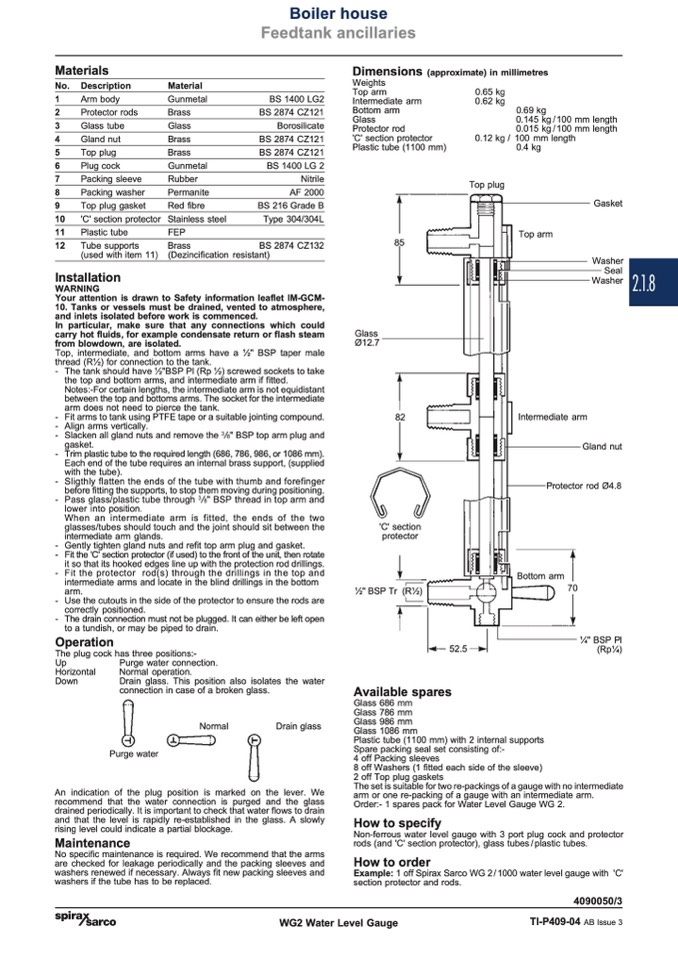

Dimensions (approximate) in millimetres

Material

Weights

Top arm

Intermediate arm

Bottom arm

Glass

Protector rod

'C' section protector

Plastic tube (1100 mm)

85

0.65 kg

0.62 kg

Gunmetal

Brass

Glass

Borosilicate

0.69 kg

0.145 kg / 100 mm length

0.015 kg / 100 mm length

BS 1400 LG2

BS 2874 CZ121

Brass

Brass

Gunmetal

Rubber

Nitrile

Top plug

Top arm

BS 2874 CZ121

BS 2874 CZ121

BS 1400 LG 2

0.12 kg / 100 mm length

0.4 kg

Permanite

Red fibre

Stainless steel

FEP

AF 2000

BS 216 Grade B

Type 304/304L

Gasket

Washer

Seal

Washer

Brass

(Dezincification resistant)

BS 2874 CZ132

Installation

WARNING

Your attention is drawn to Safety information leaflet IM-GCM-

10. Tanks or vessels must be drained, vented to atmosphere,

and inlets isolated before work is commenced.

In particular, make sure that any connections which could

carry hot fluids, for example condensate return or flash steam

Glass

from blowdown, are isolated.

Ø12.7

Top, intermediate, and bottom arms have a 1⁄2" BSP taper male

thread (R1⁄2) for connection to the tank.

- The tank should have 1⁄2"BSP Pl (Rp 1⁄2) screwed sockets to take

the top and bottom arms, and intermediate arm if fitted.

Notes:-For certain lengths, the intermediate arm is not equidistant

between the top and bottoms arms. The socket for the intermediate

arm does not need to pierce the tank.

- Fit arms to tank using PTFE tape or a suitable jointing compound.

82

- Align arms vertically.

- Slacken all gland nuts and remove the

3

/

8

" BSP top arm plug and

Intermediate arm

Gland nut

Protector rod Ø4.8

Bottom arm

70

gasket.

- Trim plastic tube to the required length (686, 786, 986, or 1086 mm).

Each end of the tube requires an internal brass support, (supplied

with the tube).

- Sligthly flatten the ends of the tube with thumb and forefinger

before fitting the supports, to stop them moving during positioning.

- Pass glass/plastic tube through

3

/

8

" BSP thread in top arm and

lower into position.

When an intermediate arm is fitted, the ends of the two

glasses/tubes should touch and the joint should sit between the

'C' section

intermediate arm glands.

protector

- Gently tighten gland nuts and refit top arm plug and gasket.

- Fit the 'C' section protector (if used) to the front of the unit, then rotate

it so that its hooked edges line up with the protection rod drillings.

- Fit the protector rod(s) through the drillings in the top and

intermediate arms and locate in the blind drillings in the bottom

arm.

1⁄2" BSP Tr (R1⁄2)

- Use the cutouts in the side of the protector to ensure the rods are

correctly positioned.

- The drain connection must not be plugged. It can either be left open

Operation

to a tundish, or may be piped to drain.

1⁄4" BSP Pl

(Rp1⁄4)

The plug cock has three positions:-

52.5

Available spares

Up

Horizontal

Down

Purge water connection.

Normal operation.

Drain glass. This position also isolates the water

connection in case of a broken glass.

Normal

Drain glass

Purge water

An indication of the plug position is marked on the lever. We

recommend that the water connection is purged and the glass

drained periodically. It is important to check that water flows to drain

and that the level is rapidly re-established in the glass. A slowly

rising level could indicate a partial blockage.

Maintenance

No specific maintenance is required. We recommend that the arms

are checked for leakage periodically and the packing sleeves and

washers renewed if necessary. Always fit new packing sleeves and

washers if the tube has to be replaced.

Glass 686 mm

Glass 786 mm

Glass 986 mm

Glass 1086 mm

Plastic tube (1100 mm) with 2 internal supports

Spare packing seal set consisting of:-

4 off Packing sleeves

8 off Washers (1 fitted each side of the sleeve)

2 off Top plug gaskets

The set is suitable for two re-packings of a gauge with no intermediate

arm or one re-packing of a gauge with an intermediate arm.

Order:- 1 spares pack for Water Level Gauge WG 2.

How to specify

Non-ferrous water level gauge with 3 port plug cock and protector

rods (and 'C' section protector), glass tubes / plastic tubes.

How to order

Example: 1 off Spirax Sarco WG 2 / 1000 water level gauge with 'C'

section protector and rods.

4090050/3

WG2 Water Level Gauge

TI-P409-04 AB Issue 3

2.1.8