1.3 Materials

Conex Compression fittings are available in yellow brass,

dezincification resistant brass and red brass (gunmetal).

Components in contact with water are manufactured

from low lead materials complying with the European

requirements for materials in contact with drinking water.

Low lead specification

• Standard material: EN 12165, CW 617N-DW

• DZR material: EN 12165, CW 511L

• Red brass (gunmetal): EN 1982, CC 499K

These materials meet the requirements of the 'UBA/4MS

list of hygienically suitable materials for drinking water',

and are ideal for all types of drinking water systems

without restriction.

1.4 Threaded connections

Conex Compression fittings are available with male and

female threaded connections. These threaded ends

incorporate a hexagon or octagon nut for tightening the

joint. They are manufactured to the following standards:

1.6 Storage and handling

It is advisable to leave the fittings in the packaging to

protect the fitting prior to installation. Please store in a

cool dry place to protect the fittings from contamination,

damage and dirt.

Cone face connectors to EN 1254-2 (BS 864: Part 2) rely

on a metal to metal seal and care should be taken to avoid

damage prior to assembly.

1.7 COSHH (Control of substances hazardous

to health)

It is the responsibility of the end user to ensure that

adequate protection is available where required and the

necessary information regarding possible health and

safety regulations is adhered to. Copper and copper

alloy fittings are considered non-hazardous under normal

circumstances.

1.8 Finish availability

Apart from the natural brass finish, Conex Compression

fittings are also available in nickel or chrome plated finish

in accordance with EN 248.

Note: It is recommended that you contact our customer

service team for availability of any of our Conex

Compression fittings in the plated versions.

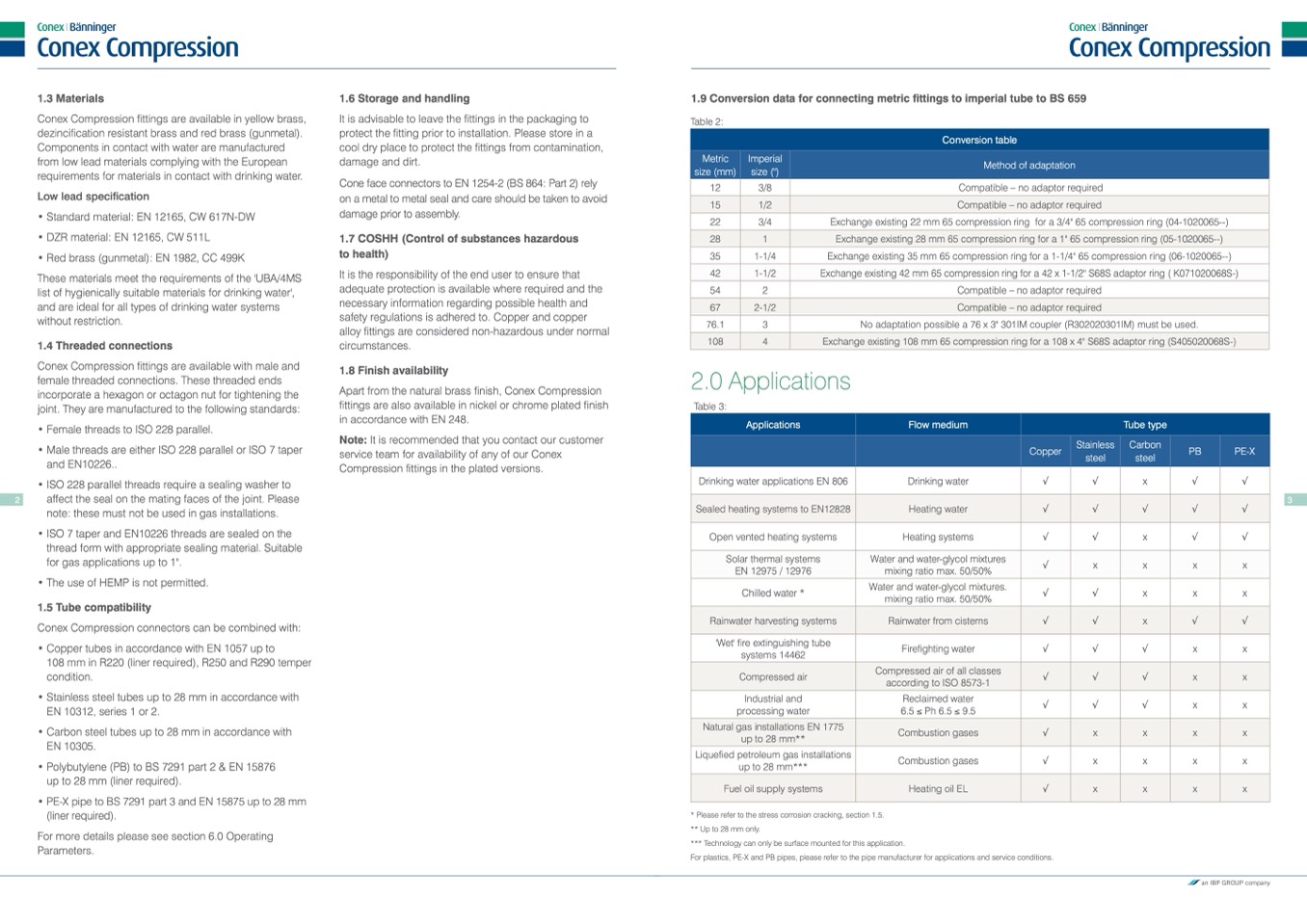

1.9 Conversion data for connecting metric fittings to imperial tube to BS 659

Table 2:

Conversion table

Metric

size (mm)

Imperial

size (")

Method of adaptation

12

3/8

Compatible – no adaptor required

15

1/2

Compatible – no adaptor required

22

3/4

Exchange existing 22 mm 65 compression ring for a 3/4" 65 compression ring (04-1020065--)

28

1

Exchange existing 28 mm 65 compression ring for a 1" 65 compression ring (05-1020065--)

35

1-1/4

Exchange existing 35 mm 65 compression ring for a 1-1/4" 65 compression ring (06-1020065--)

42

1-1/2

Exchange existing 42 mm 65 compression ring for a 42 x 1-1/2" S68S adaptor ring ( K071020068S-)

54

2

Compatible – no adaptor required

67

2-1/2

Compatible – no adaptor required

76.1

3

No adaptation possible a 76 x 3" 301IM coupler (R302020301IM) must be used.

108

4

Exchange existing 108 mm 65 compression ring for a 108 x 4" S68S adaptor ring (S405020068S-)

2.0 Applications

Table 3:

Applications

Flow medium

Tube type

Copper

Stainless

steel

Carbon

steel

PB

PE-X

Drinking water applications EN 806

Drinking water

√

√

x

√

√

Sealed heating systems to EN12828

Heating water

√

√

√

√

√

Open vented heating systems

Heating systems

√

√

x

√

√

Solar thermal systems

EN 12975 / 12976

Water and water-glycol mixtures

mixing ratio max. 50/50%

√

x

x

x

x

Chilled water *

Water and water-glycol mixtures.

mixing ratio max. 50/50%

√

√

x

x

x

Rainwater harvesting systems

Rainwater from cisterns

√

√

x

√

√

'Wet' fire extinguishing tube

systems 14462

Firefighting water

√

√

√

x

x

Compressed air

Compressed air of all classes

according to ISO 8573-1

√

√

√

x

x

Industrial and

processing water

Reclaimed water

6.5 ≤ Ph 6.5 ≤ 9.5

√

√

√

x

x

Natural gas installations EN 1775

up to 28 mm**

Combustion gases

√

x

x

x

x

Liquefied petroleum gas installations

up to 28 mm***

Combustion gases

√

x

x

x

x

Fuel oil supply systems

Heating oil EL

√

x

x

x

x

•

•

•

2

•

•

Female threads to ISO 228 parallel.

Male threads are either ISO 228 parallel or ISO 7 taper

and EN10226..

ISO 228 parallel threads require a sealing washer to

affect the seal on the mating faces of the joint. Please

note: these must not be used in gas installations.

ISO 7 taper and EN10226 threads are sealed on the

thread form with appropriate sealing material. Suitable

for gas applications up to 1".

The use of HEMP is not permitted.

3

1.5 Tube compatibility

Conex Compression connectors can be combined with:

• Copper tubes in accordance with EN 1057 up to

108 mm in R220 (liner required), R250 and R290 temper

condition.

• Stainless steel tubes up to 28 mm in accordance with

EN 10312, series 1 or 2.

• Carbon steel tubes up to 28 mm in accordance with

EN 10305.

• Polybutylene (PB) to BS 7291 part 2 & EN 15876

up to 28 mm (liner required).

• PE-X pipe to BS 7291 part 3 and EN 15875 up to 28 mm

(liner required).

For more details please see section 6.0 Operating

Parameters.

* Please refer to the stress corrosion cracking, section 1.5.

** Up to 28 mm only.

*** Technology can only be surface mounted for this application.

For plastics, PE-X and PB pipes, please refer to the pipe manufacturer for applications and service conditions.