3.0 Product Suitability

The applications and tube type refered to in Table 3,

must be ahered to when using and connecting Conex

compression Brass and Copper Alloy fittings.

3.0.1 Drinking water installations

Drinking water installations must be planned and

installed in accordance with local and national water

byelaws and regulations and standards such as EN 806.

Conex compression fittings have several accreditations

for use with drinking water systems. For drinking

water applications it is important to select the correct

materials, EN 806 specifies requirements for drinking

water applications that must be adhered to. Conex

Compresion fittings are made from materials that fully

comply with European drinking water requirements. Conex

Compression is also certified by Bureau Veritas for marine

usage Ref. cert number . SMS.W.11./62847/D.0 and must

be used within the range of recognition of NR320.

3.0.2 Heating and cooling systems

In closed heating, cooling and chilled water systems, there

is generally an absence of oxygen which greatly reduces

the likelihood of corrosion. This means a range of metallic

materials may be used without the risk of corrosion; flow

direction does not need to be taken into consideration.

3.1 Thermal Expansion

3.1.1 Effects of expansion

The coefficient of linear expansion for copper is 16.8

x 10-6 °C. For example, a 10 m length of copper tube,

irrespective of its size, wall thickness or temper, will

increase in length by 10.8 mm temperature rise of 60

°C. Tubes installed on hot water services must be free to

accommodate this expansion; otherwise stresses will build

up in the pipework that may lead to joints being pulled

apart and/or tubes fracturing. Clearly the magnitude and

frequency of such changes in length will determine the life

of the joint or failure of the tube.

The table on page 5 shows the amount of tube expansion

for a given temperature rise. In the case of tube in

domestic hot water and heating installations the limited

size of rooms and hence straight tube runs, together with

the many bends and offsets that normally occur, will result

in thermal movement being accommodated automatically.

However, where long straight tube runs, exceeding 10 m,

are encountered, allowance for expansion should be made.

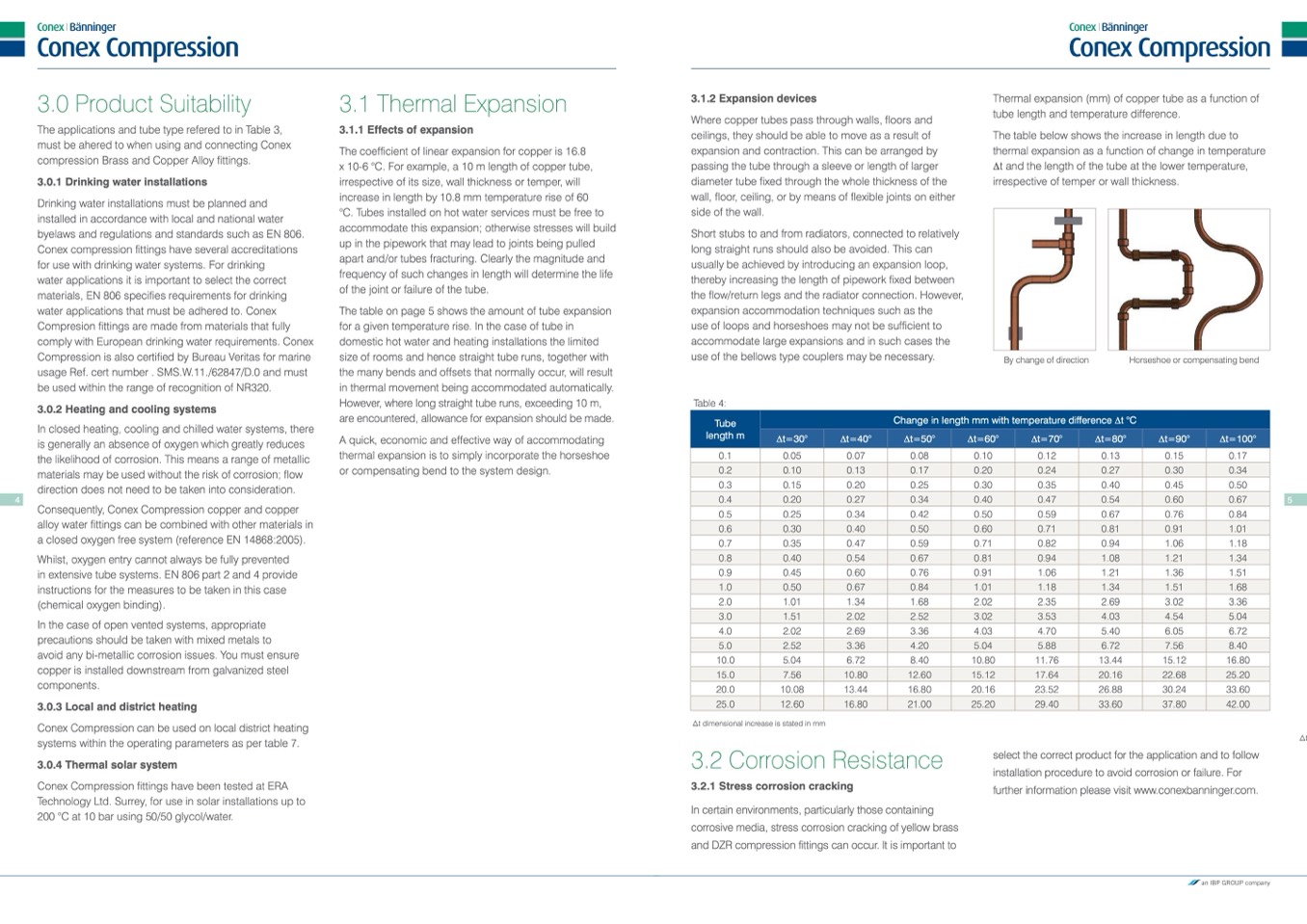

A quick, economic and effective way of accommodating

thermal expansion is to simply incorporate the horseshoe

or compensating bend to the system design.

3.1.2 Expansion devices

Where copper tubes pass through walls, floors and

ceilings, they should be able to move as a result of

expansion and contraction. This can be arranged by

passing the tube through a sleeve or length of larger

diameter tube fixed through the whole thickness of the

wall, floor, ceiling, or by means of flexible joints on either

side of the wall.

Short stubs to and from radiators, connected to relatively

long straight runs should also be avoided. This can

usually be achieved by introducing an expansion loop,

thereby increasing the length of pipework fixed between

the flow/return legs and the radiator connection. However,

expansion accommodation techniques such as the

use of loops and horseshoes may not be sufficient to

accommodate large expansions and in such cases the

use of the bellows type couplers may be necessary.

Thermal expansion (mm) of copper tube as a function of

tube length and temperature difference.

The table below shows the increase in length due to

thermal expansion as a function of change in temperature

∆t and the length of the tube at the lower temperature,

irrespective of temper or wall thickness.

Tube

length m

Change in length mm with temperature difference ∆t °C

∆t=30°

∆t=40°

∆t=50°

∆t=60°

∆t=70°

∆t=80°

∆t=90°

∆t=100°

0.2

0.10

0.13

0.17

0.20

0.24

0.27

0.30

0.34

0.4

0.20

0.27

0.34

0.40

0.47

0.54

0.60

0.67

4

5

Consequently, Conex Compression copper and copper

alloy water fittings can be combined with other materials in

a closed oxygen free system (reference EN 14868:2005).

Whilst, oxygen entry cannot always be fully prevented

in extensive tube systems. EN 806 part 2 and 4 provide

instructions for the measures to be taken in this case

(chemical oxygen binding).

In the case of open vented systems, appropriate

precautions should be taken with mixed metals to

avoid any bi-metallic corrosion issues. You must ensure

copper is installed downstream from galvanized steel

components.

3.0.3 Local and district heating

Conex Compression can be used on local district heating

systems within the operating parameters as per table 7.

3.0.4 Thermal solar system

Conex Compression fittings have been tested at ERA

Technology Ltd. Surrey, for use in solar installations up to

200 °C at 10 bar using 50/50 glycol/water.

Table 4:

0.1

0.05

0.3

0.15

0.07

0.08

0.20

0.25

By change of direction

0.10

0.12

0.30

0.35

Horseshoe or compensating bend

0.13

0.15

0.17

0.40

0.45

0.50

0.5

0.25

0.34

0.7

0.35

0.47

0.9

0.45

0.60

2.0

1.01

1.34

4.0

2.02

2.69

10.0

5.04

6.72

20.0

10.08

13.44

t dimensional increase is stated in mm

3.2 Corrosion Resistance

3.2.1 Stress corrosion cracking

In certain environments, particularly those containing

corrosive media, stress corrosion cracking of yellow brass

and DZR compression fittings can occur. It is important to

0.42

0.50

0.59

0.71

0.76

0.91

1.68

2.02

3.36

4.03

8.40

10.80

16.80

20.16

0.59

0.67

0.82

0.94

1.06

1.21

2.35

2.69

4.70

5.40

11.76

13.44

23.52

26.88

0.76

0.84

1.06

1.18

1.36

1.51

3.02

3.36

6.05

6.72

15.12

16.80

30.24

33.60

0.6

0.30

0.40

0.50

0.60

0.71

0.81

0.91

1.01

0.8

0.40

0.54

0.67

0.81

0.94

1.08

1.21

1.34

1.0

0.50

0.67

0.84

1.01

1.18

1.34

1.51

1.68

3.0

1.51

2.02

2.52

3.02

3.53

4.03

4.54

5.04

5.0

2.52

3.36

4.20

5.04

5.88

6.72

7.56

8.40

15.0

7.56

10.80

12.60

15.12

17.64

20.16

22.68

25.20

25.0

12.60

16.80

21.00

25.20

29.40

33.60

37.80

42.00

select the correct product for the application and to follow

installation procedure to avoid corrosion or failure. For

further information please visit www.conexbanninger.com.

t