Contents

1.0

General ..............................................................................................................................................................................1

1.1 Quality and certification

1.2 Product design

1.3 Materials

1.4 Threaded connections

1.5 Tube compatibility

1.6 Storage and handling

1.7 COSHH (Control of Substances Hazardous to Health)

1.8 Finish availability

1.9 Conversion data for connecting metric fittings to imperial tube

Applications ......................................................................................................................................................................3

Product Suitability..............................................................................................................................................................4

3.0.1 Drinking water installations

3.0.2 Heating and cooling systems

3.0.3 Local and district heating

3.0.4 Thermal solar system

Thermal Expansion............................................................................................................................................................4

3.1.1 Effects of expansion

3.1.2 Expansion devices

Corrosion Resistance ..........................................................................................................................................................5

3.2.1 Stress corrosion cracking

3.2.2 Corrosion on copper and copper alloys

Pressure Testing...................................................................................................................................................................6

System Commissioning ......................................................................................................................................................7

3.4.1 Flushing of water installations

3.4.2 Water softening

Jointing Instructions ............................................................................................................................................................8

4.1 Sizes 6 - 54 mm

4.2 Minimum distances and insertion depths

4.3 Threaded joints for water applications

4.4 Connecting to plastic pipes

4.5 Flange fittings – sizes 67 to 108 mm

4.6 Internal reducers

4.7 Jointing instructions for gas applications

Other Installations .............................................................................................................................................................12

5.1 Solar installations

5.2 Gas installations

Operating Parameters .......................................................................................................................................................13

6.1 Operating temperature and pressures with metal tubes

6.2 Operating temperatures and pressures with plastic pipe.

Loss Coefficients ...............................................................................................................................................................14

The Range .........................................................................................................................................................................16

Guarantee .........................................................................................................................................................................42

2.0

3.0

3.1

3.2

3.3

3.4

4.0

5.0

6.0

7.0

8.0

9.0

1.0 General

Conex Compression fittings are manufactured from high

quality brass materials which ensures a permanently

tight and secure connection, without the use of special

tooling or additional sealant. These fittings are suitable for

connecting a wide range of tubes, including copper tubes

in accordance with EN 1057, carbon steel to EN 10305,

stainless steel to EN 10312 and plastic pipes to BS 7291,

EN 15875 and EN 15876.

1.1 Quality and certification

Conex Bänninger has 110 years of experience in

manufacturing innovative products and operates an

accredited Quality Managements System to ISO 9001.

Conex Compression fittings are tested and approved

for use with drinking water up to 108 mm and for gas

applications up to 28 mm. Tested and certified by

independent European certification bodies such as WRAS

(Water Regulations Advisory Scheme) confirming their

suitability and reliability for drinking water use.

Conex Compression fittings are approved for various

applications and certified by the following bodies:

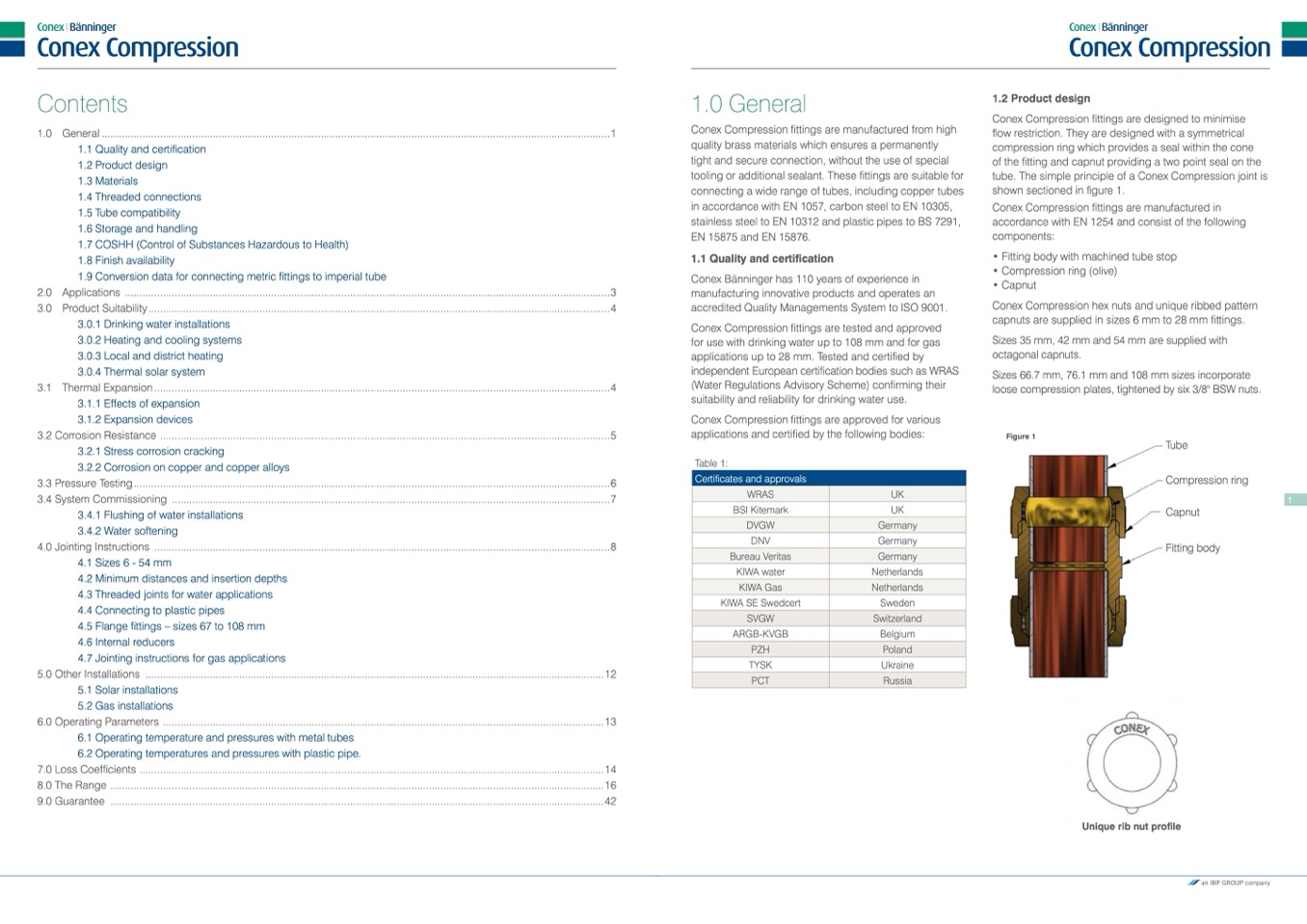

1.2 Product design

Conex Compression fittings are designed to minimise

flow restriction. They are designed with a symmetrical

compression ring which provides a seal within the cone

of the fitting and capnut providing a two point seal on the

tube. The simple principle of a Conex Compression joint is

shown sectioned in figure 1.

Conex Compression fittings are manufactured in

accordance with EN 1254 and consist of the following

components:

• Fitting body with machined tube stop

• Compression ring (olive)

• Capnut

Conex Compression hex nuts and unique ribbed pattern

capnuts are supplied in sizes 6 mm to 28 mm fittings.

Sizes 35 mm, 42 mm and 54 mm are supplied with

octagonal capnuts.

Sizes 66.7 mm, 76.1 mm and 108 mm sizes incorporate

loose compression plates, tightened by six 3/8" BSW nuts.

Table 1:

BSI Kitemark

DNV

KIWA water

KIWA SE Swedcert

ARGB-KVGB

TYSK

1

Figure 1

Tube

Compression ring

Capnut

Fitting body

Certificates and approvals

WRAS

UK

UK

Germany

Netherlands

Sweden

Belgium

Ukraine

DVGW

Germany

Bureau Veritas

Germany

KIWA Gas

Netherlands

SVGW

Switzerland

PZH

Poland

PCT

Russia

Unique rib nut profile