Boiler house

Feedtank ancillaries

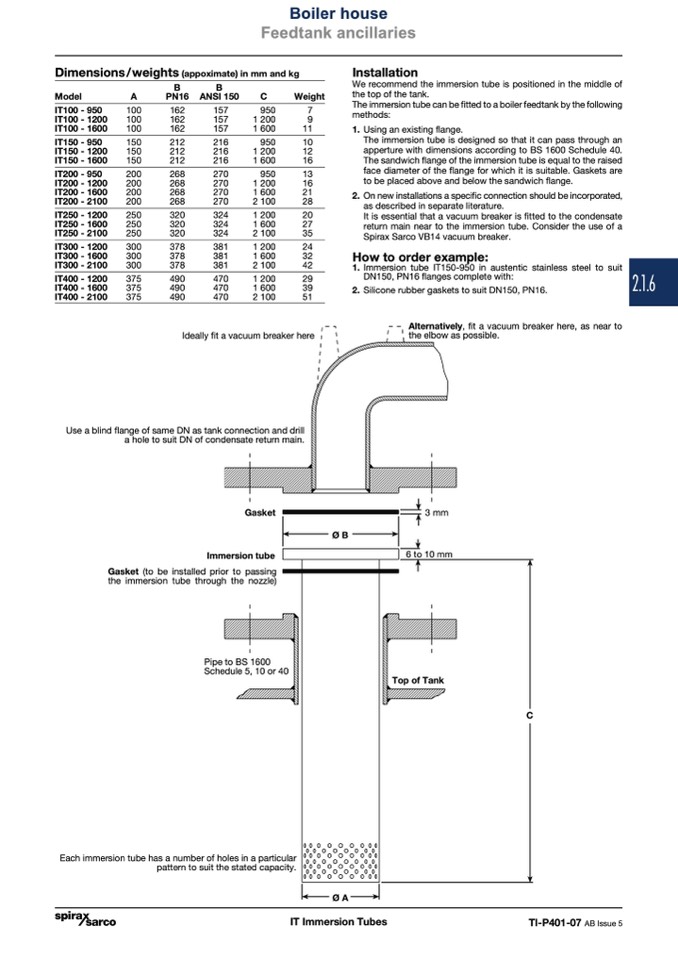

Dimensions / weights (appoximate) in mm and kg

Installation

Model

IT100 - 950

IT100 - 1200

IT100 - 1600

IT150 - 950

IT150 - 1200

IT150 - 1600

IT200 - 950

IT200 - 1200

IT200 - 1600

IT200 - 2100

IT250 - 1200

IT250 - 1600

IT250 - 2100

IT300 - 1200

IT300 - 1600

IT300 - 2100

IT400 - 1200

IT400 - 1600

IT400 - 2100

B

B

We recommend the immersion tube is positioned in the middle of

the top of the tank.

The immersion tube can be fitted to a boiler feedtank by the following

methods:

A

PN16

100

162

100

162

100

162

150

212

150

212

150

212

200

268

200

268

200

268

200

268

250

320

250

320

250

320

300

378

300

378

300

378

375

490

375

490

375

490

ANSI 150

C

Weight

157

950

7

157

1 200

9

157

1 600

216

950

10

11

1.

2.

Using an existing flange.

The immersion tube is designed so that it can pass through an

apperture with dimensions according to BS 1600 Schedule 40.

The sandwich flange of the immersion tube is equal to the raised

face diameter of the flange for which it is suitable. Gaskets are

to be placed above and below the sandwich flange.

On new installations a specific connection should be incorporated,

as described in separate literature.

It is essential that a vacuum breaker is fitted to the condensate

return main near to the immersion tube. Consider the use of a

Spirax Sarco VB14 vacuum breaker.

216

1 200

216

1 600

12

16

270

270

270

270

324

324

324

381

381

381

470

470

470

950

13

1 200

16

1 600

21

2 100

28

1 200

1 600

27

2 100

35

1 200

24

1 600

32

2 100

42

1 200

29

1 600

39

2 100

51

20

Ideally fit a vacuum breaker here

How to order example:

1. Immersion tube IT150-950 in austentic stainless steel to suit

DN150, PN16 flanges complete with:

2. Silicone rubber gaskets to suit DN150, PN16.

Alternatively, fit a vacuum breaker here, as near to

the elbow as possible.

Use a blind flange of same DN as tank connection and drill

a hole to suit DN of condensate return main.

Gasket

Immersion tube

Gasket (to be installed prior to passing

the immersion tube through the nozzle)

Pipe to BS 1600

Schedule 5, 10 or 40

3 mm

6 to 10 mm

ØB

Top of Tank

C

r

.

Each immersion tube has a number of holes in a particula

pattern to suit the stated capacity

ØA

IT Immersion Tubes

TI-P401-07 AB Issue 5

2.1.6