Boiler house

Feedtank ancillaries

ISO 9001

2.1.1

Total steam

generation

rate (kg/h)

Mixing

unit

Tank depth

1250

1500

2000

2500

Mixing unit/immersion tube selection

5 000

DN150

MU150

IT-950

MU150

IT-1200

MU150

IT-1600

MU150

IT-2100

10 000

DN200

MU200

IT-950

MU200

IT-1200

MU200

IT-1600

MU200

IT-2100

20 000

DN250

MU250

IT-950

MU250

IT-1200

MU250

IT-1600

MU250

IT-2100

30 000

DN300

MU300

IT-950

MU300

IT-1200

MU300

IT-1600

MU300

IT-2100

50 000

DN400

MU400

IT-950

MU400

IT-1200

MU400

IT-1600

MU400

IT-2100

TI-P401-25

AB Issue 3

Cert. No. LRQ 0963008

DH Type

Flash Condensing Deaerator Heads

A simple low cost solution for deaerating boiler feedwater at atmospheric pressure

•

Mixes hot and cold incoming flows

•

Liberates oxygen and other gases

•

Stainless steel for long maintenance free life

•

Easy to install

Description

Spirax Sarco flash condensing deaerator head is designed to mix

incoming flows of cold make-up, condensate return and flash

steam to the boiler feedtank. This mixing action is achieved by

directing the downward flow through a baffle arrangement within

the unit. This liberates dissolved gases from the cold make-up,

which are vented to atmosphere. The cold make-up inlet is fitted

with a spray screen which diffuses the flow, increasing its surface

area to promote thorough mixing with the condensate and

flash steam.

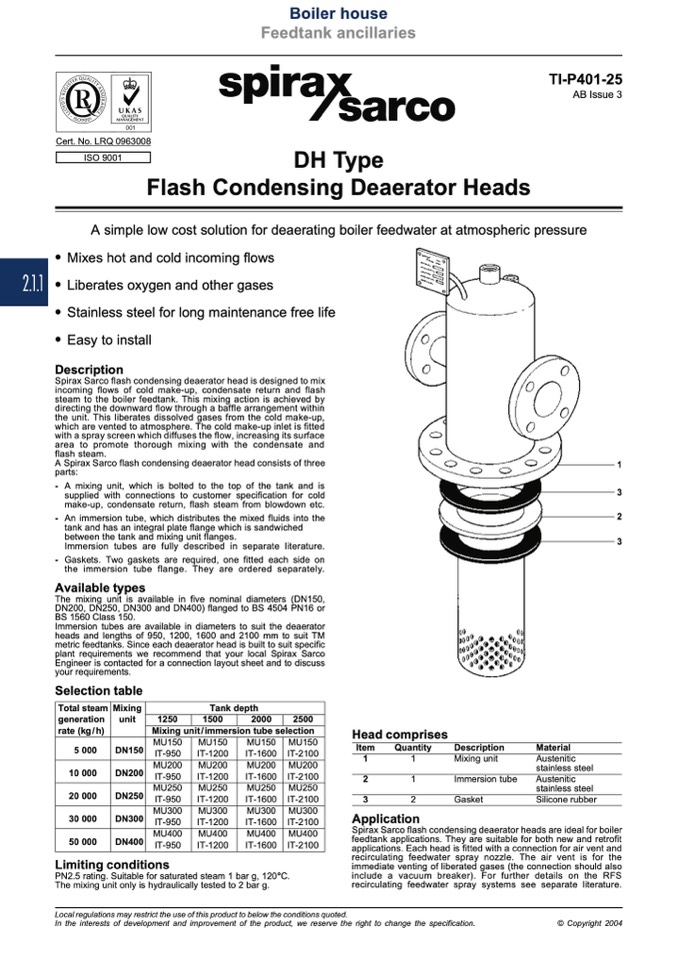

A Spirax Sarco flash condensing deaerator head consists of three

parts:

1

3

2

3

- A mixing unit, which is bolted to the top of the tank and is

supplied with connections to customer specification for cold

make-up, condensate return, flash steam from blowdown etc.

- An immersion tube, which distributes the mixed fluids into the

tank and has an integral plate flange which is sandwiched

between the tank and mixing unit flanges.

Immersion tubes are fully described in separate literature.

- Gaskets. Two gaskets are required, one fitted each side on

the immersion tube flange. They are ordered separately.

Available types

The mixing unit is available in five nominal diameters (DN150,

DN200, DN250, DN300 and DN400) flanged to BS 4504 PN16 or

BS 1560 Class 150.

Immersion tubes are available in diameters to suit the deaerator

heads and lengths of 950, 1200, 1600 and 2100 mm to suit TM

metric feedtanks. Since each deaerator head is built to suit specific

plant requirements we recommend that your local Spirax Sarco

Engineer is contacted for a connection layout sheet and to discuss

your requirements.

Selection table

Head comprises

Item

Quantity

1

1

2

1

3

2

Application

Description

Mixing unit

Immersion tube

Gasket

Material

Austenitic

stainless steel

Austenitic

stainless steel

Silicone rubber

Limiting conditions

PN2.5 rating. Suitable for saturated steam 1 bar g, 120°C.

The mixing unit only is hydraulically tested to 2 bar g.

Spirax Sarco flash condensing deaerator heads are ideal for boiler

feedtank applications. They are suitable for both new and retrofit

applications. Each head is fitted with a connection for air vent and

recirculating feedwater spray nozzle. The air vent is for the

immediate venting of liberated gases (the connection should also

include a vacuum breaker). For further details on the RFS

recirculating feedwater spray systems see separate literature.

Local regulations may restrict the use of this product to below the conditions quoted.

In the interests of development and improvement of the product, we reserve the right to change the specification.

© Copyright 2004