COMPLIANCE

FACTORY ACCEPTANCE TEST

AN AIR HANDLING

UNIT FULLY

COMPLIANT TO...

ISO 15138:2007

Petroleum and natural gas industries - Offshore production

and installations - Heating, ventilation and air-conditioning:

• Annex A.12 in all the functional requirements, access doors

and even, upon Customer request, factory fitted controls

• All the components related Annexes:

- A.4 - Heating coils ...

- A.5 - Cooling coils ...

- A.6 - Humidifiers

- A.7 - Fans

- A.8 - Sound attenuators

- A.10 - General dampers

• Annex E for duct interface flanges.

Statoil TR 1562

HVAC Design and fabrication requirements:

All the units are designed to optimized the space inside the casing

to minimize the pressure drop of the components;

The casing Air leakage rate comply with class L2 (EN 1886: 2007).

All materials and components comply with the fabrication

requirements:

• “Draining” type F7 class filters (EN 779);

• Titanium coils when seawater circulating or above 60°C, AISI;

• 316L may be used in fresh water cooling coil;

• AISI 316L Electric heating coil Ex-d(e) T1-4 step or proportional

control/thyristor with Ex-d IIB,C T1-T6 safety thermostats;

• Spark-proof Direct-driven Plug-fan preferred choice made

of AISI 316L capable of 160% nominal duty in 2 x 50% systems,

fixed mounted accelerometers available cabled to an external

junction box;

• ATEX 2014/34/EU - Ex marking for classified equipment.

Shell DEP

DEP 37.76.10.10 HVAC for offshore installations (amendments/

supplements to ISO 15138);

DEP 31.76.10.11-Gen. Installation, testing and balancing, and

commissioning of HVAC systems.

Total

General Specification HVAC GS EP HVA 202;

Air Handling Unit (AHU).

EN 14986:2007

Design of fans working in potentially explosive atmospheres.

EN 13463-1:2009

Non-electrical equipment for use in potentially explosive

atmospheres. Basic method and requirements.

EN 60079-14

Electrical apparatus for explosive gas atmospheres - Part 14:

Electrical installations in hazardous areas (other than mines).

EN 60079-17

Explosive atmospheres. Electrical installations inspection

and maintenance.

EN 15198:2007

Methodology for the risk assessment of non-electrical equipment

and components for intended use in potentially explosive

atmospheres.

CLC/TR 50404:2003

Electrostatics - Code of practice for the avoidance of hazards due

to static electricity.

CLC/TC31

Electrical apparatus for potentially explosive atmospheres

The Air handling units are CE marked in conformity to the following

standard:

• Directive 2006/42/EC on machinery;

• Directive 2004/108/EC Electromagnetic Compatibility (EMC);

• Directive 2006/95/EC Low Voltage Directive (LVD).

The Air handling units can be CE - ex marked in conformity to

the 2014/34/EU - ATEX Directive up to Category 2 Zone 1 with

the deposit of the Technical File (Annex VIII) at Bureau Veritas

Italia notified body no. 1370.

BVI/ATEX/ITA/15/069

II 2/2 G II TX (-20°C < Tamb < +40°C)

EN 1886:2007

Air handling units Mechanical performance

The mechanical performance of the Roccheggiani Air Handling Units

have been tested in the TÜV SÜD laboratories (rep. no. 6889) under

the Eurovent Certification program and the units belong to the

following classes:

• Mechanical strength of the casing: D1(M) with maximum

measured deflection 2,6mm/m.

Units can withstand to ±2500 Pa with no permanent deflections.

• Casing Air leakage: L2(M)

• Filter by-pass leakage: F9 - percent leakage < 0,1%

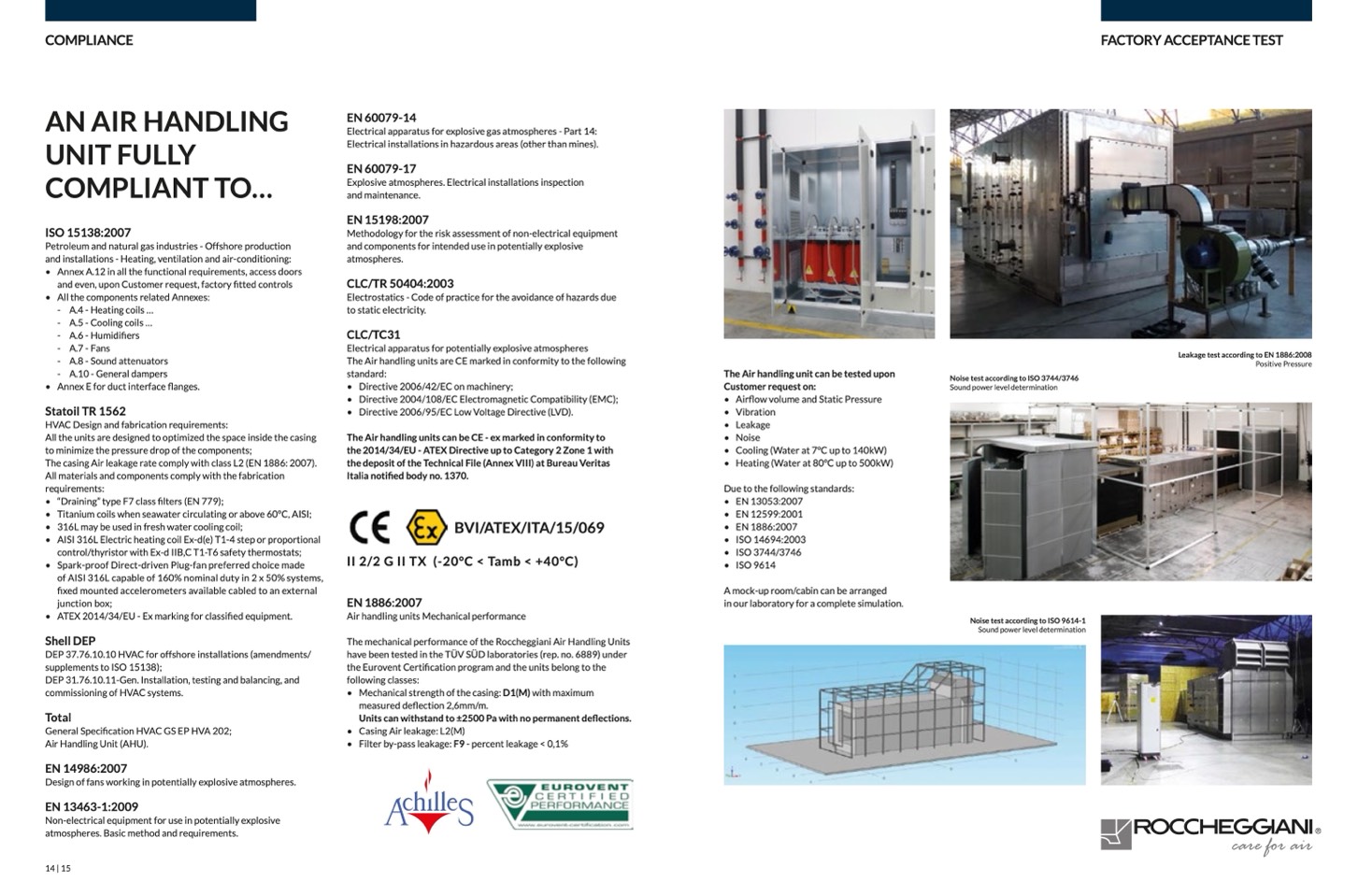

Leakage test according to EN 1886:2008

Positive Pressure

The Air handling unit can be tested upon

Customer request on:

• Airflow volume and Static Pressure

• Vibration

• Leakage

• Noise

• Cooling (Water at 7°C up to 140kW)

• Heating (Water at 80°C up to 500kW)

Due to the following standards:

• EN 13053:2007

• EN 12599:2001

• EN 1886:2007

• ISO 14694:2003

• ISO 3744/3746

• ISO 9614

A mock-up room/cabin can be arranged

in our laboratory for a complete simulation.

Noise test according to ISO 3744/3746

Sound power level determination

Noise test according to ISO 9614-1

Sound power level determination

14 | 15