DESIGN TOOLS

DESIGN TOOLS

THE STRONGEST CONSTRUCTION

FOR THE HARDEST CONDITIONS

12 | 13

Offer

Project

Unit size

Panel inside

Panel outside

Panel inside bottom

Profiles

Guides

Insulation

Corners

PanelreactiontofireclassduetoUNI9177: 0(ZERO)

Certified mechanical performances due to EN 1886:2007

Mechanical stability

Casing leakage -400 Pa

Filter by-pass leakage

Casing leakage +700 Pa

Position

01

RGS

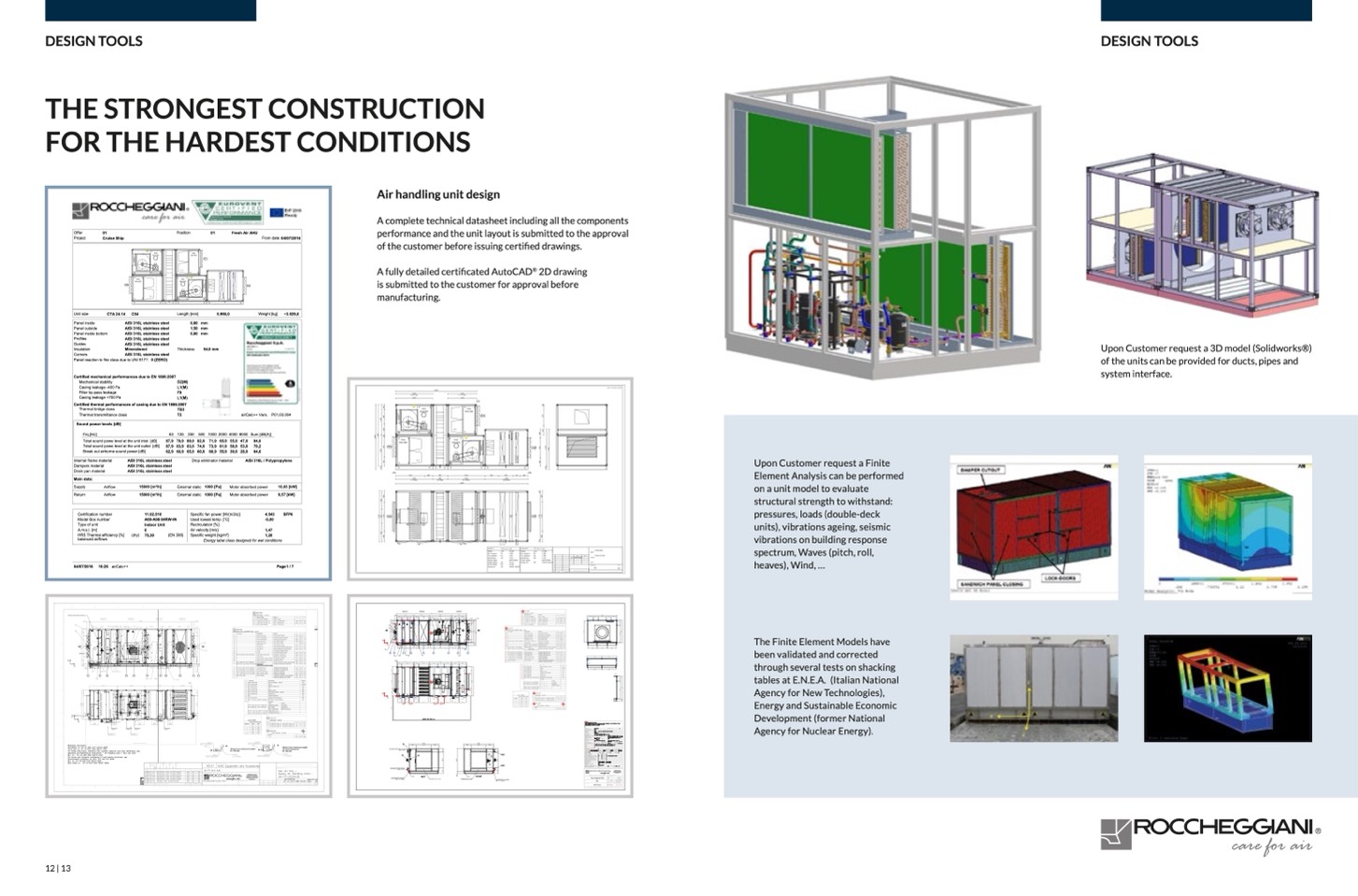

Air handling unit design

A complete technical datasheet including all the components

performance and the unit layout is submitted to the approval

of the customer before issuing certified drawings.

A fully detailed certificated AutoCAD

®

2D drawing

is submitted to the customer for approval before

manufacturing.

Internal frame material

Dampers material

Drain pan material

AISI 316L stainless steel

AISI 316L stainless steel

AISI 316L stainless steel

15000 [m3/h]

15000 [m3/h]

AISI 316L / Polypropylene

Upon Customer request a Finite

Element Analysis can be performed

on a unit model to evaluate

structural strength to withstand:

pressures, loads (double-deck

units), vibrations ageing, seismic

vibrations on building response

spectrum, Waves (pitch, roll,

heaves), Wind, ...

The Finite Element Models have

been validated and corrected

through several tests on shacking

tables at E.N.E.A. (Italian National

Agency for New Technologies),

Energy and Sustainable Economic

Development (former National

Agency for Nuclear Energy).

Main data:

Supply

Return

Airflow

Airflow

External static

External static

1000 [Pa]

1000 [Pa]

Motor absorbed power

Motor absorbed power

10,03 [kW]

9,57 [kW]

SFP6

Certification number

Model Box number

Type of unit

A.m.s.l. [m]

HRS Thermal efficiency [%]

balanced airflows

(dry)

11.02.510

-A08-A08-54RW-IN

Indoor Unit

0

75,30

Specific fan power [W/(m3/s)]

4.543

Used lowest temp. [°C]

-5,00

Recirculation [%]

Air velocity [m/s]

1,47

Specific weight [kg/m3]

1,20

04/07/2016

18:26

airCalc++

Page1 / 7

01

Cruise Ship

Fresh Air AHU

SUP

From date 04/07/2016

D

N

6

5

D

N

5

0

R

G

P

1

8

0

x

1

5

3

0

D

N

5

0

D

N

6

5

ODA

CTA 24.14

AISI 316L stainless

Length [mm]

5.990,0

Weight [kg]

~3.529,0

RGS

540x1260

F7

RGS

630x1260

C54

AISI 316L stainless

AISI 316L stainless

AISI 316L stainless

AISI 316L stainless

Mineralwool

steel

steel

steel

steel

steel

0,80 mm

1,50 mm

0,80 mm

AISI 316L stainless steel

Thickness

D2(M)

L1(M)

F9

L1(M)

54,0 mm

Upon Customer request a 3D model (Solidworks®)

of the units can be provided for ducts, pipes and

system interface.

Certified thermal performances of casing due to EN 1886:2007

Thermal bridge class

TB3

Thermal transmittance class

T2

Sound power levels [dB]

Frq.[Hz]

Total sound powe level at the unit inlet [dB]

P01.00.004

F7

RGS

630x1260

540x1260

87,9 79,9 89,9 82,9 71,9 65,9 55,9

Total sound powe level at the unit outlet [dB] 87,9 83,9 83,9 74,9 73,9 61,9 58,9

47,9 84,0

53,9 79,2

28,9 64,6

Break out airborne sound power [dB]

62,9

60,9 65,9 60,9 60,9 55,9 39,9

Drop eliminator material

ETA

airCalc++ Vers.

63 125 250 500 1000 2000 4000 8000 Sum [dB(A)]

(EN 308)

Energy label class designed for wet conditions