MARINE AIR HANDLING UNITS

MARINE AIR HANDLING UNITS

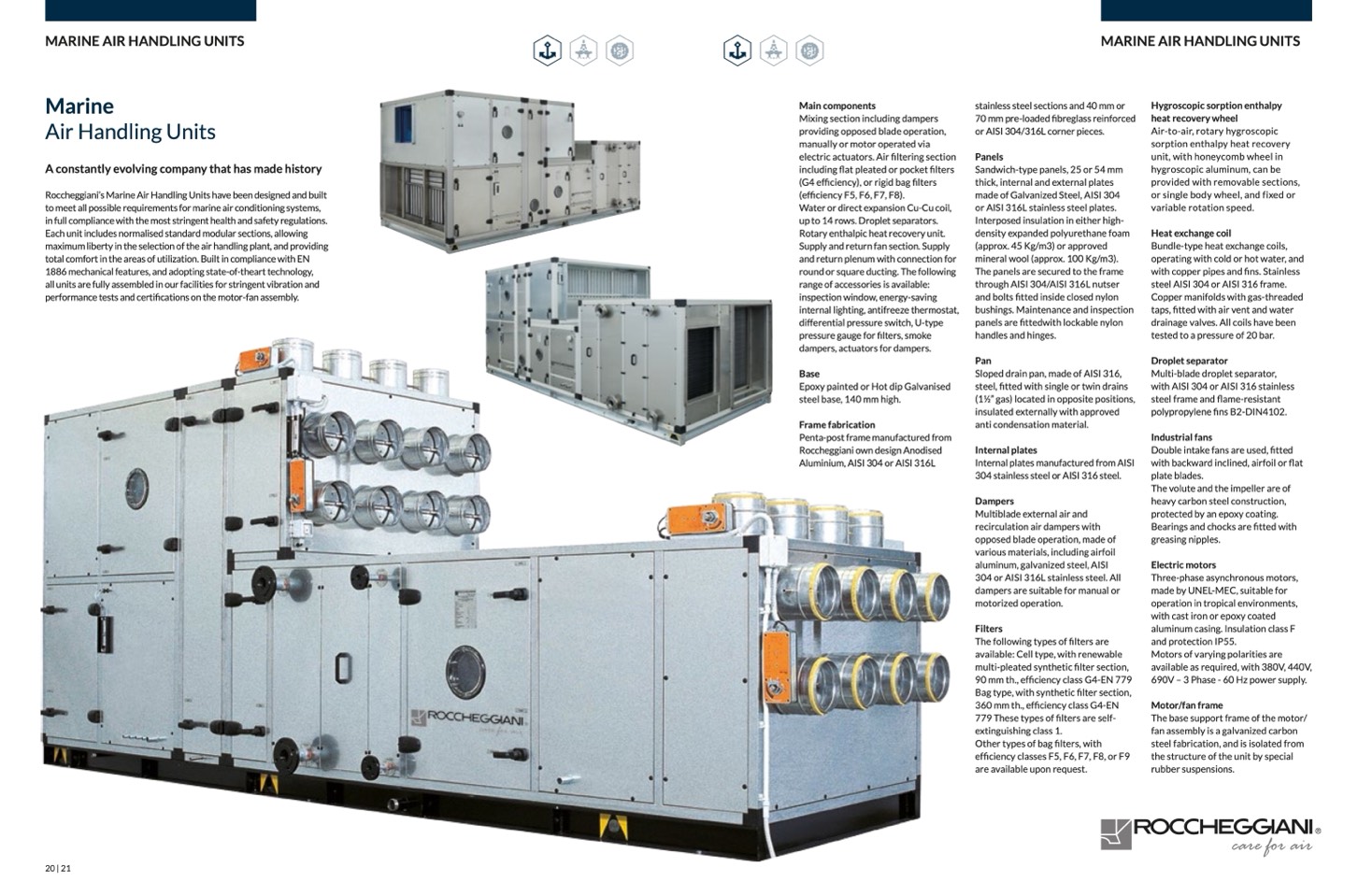

Marine

Air Handling Units

A constantly evolving company that has made history

Roccheggiani’s Marine Air Handling Units have been designed and built

to meet all possible requirements for marine air conditioning systems,

in full compliance with the most stringent health and safety regulations.

Each unit includes normalised standard modular sections, allowing

maximum liberty in the selection of the air handling plant, and providing

total comfort in the areas of utilization. Built in compliance with EN

1886 mechanical features, and adopting state-of-theart technology,

all units are fully assembled in our facilities for stringent vibration and

performance tests and certifications on the motor-fan assembly.

Main components

Mixing section including dampers

providing opposed blade operation,

manually or motor operated via

electric actuators. Air filtering section

including flat pleated or pocket filters

(G4 efficiency), or rigid bag filters

(efficiency F5, F6, F7, F8).

Water or direct expansion Cu-Cu coil,

up to 14 rows. Droplet separators.

Rotary enthalpic heat recovery unit.

Supply and return fan section. Supply

and return plenum with connection for

round or square ducting. The following

range of accessories is available:

inspection window, energy-saving

internal lighting, antifreeze thermostat,

differential pressure switch, U-type

pressure gauge for filters, smoke

dampers, actuators for dampers.

Base

Epoxy painted or Hot dip Galvanised

steel base, 140 mm high.

Frame fabrication

Penta-post frame manufactured from

Roccheggiani own design Anodised

Aluminium, AISI 304 or AISI 316L

stainless steel sections and 40 mm or

70 mm pre-loaded fibreglass reinforced

or AISI 304/316L corner pieces.

Panels

Sandwich-type panels, 25 or 54 mm

thick, internal and external plates

made of Galvanized Steel, AISI 304

or AISI 316L stainless steel plates.

Interposed insulation in either high-

density expanded polyurethane foam

(approx. 45 Kg/m3) or approved

mineral wool (approx. 100 Kg/m3).

The panels are secured to the frame

through AISI 304/AISI 316L nutser

and bolts fitted inside closed nylon

bushings. Maintenance and inspection

panels are fittedwith lockable nylon

handles and hinges.

Pan

Sloped drain pan, made of AISI 316,

steel, fitted with single or twin drains

(11⁄2” gas) located in opposite positions,

insulated externally with approved

anti condensation material.

Internal plates

Internal plates manufactured from AISI

304 stainless steel or AISI 316 steel.

Dampers

Multiblade external air and

recirculation air dampers with

opposed blade operation, made of

various materials, including airfoil

aluminum, galvanized steel, AISI

304 or AISI 316L stainless steel. All

dampers are suitable for manual or

motorized operation.

Filters

The following types of filters are

available: Cell type, with renewable

multi-pleated synthetic filter section,

90 mm th., efficiency class G4-EN 779

Bag type, with synthetic filter section,

360 mm th., efficiency class G4-EN

779 These types of filters are self-

extinguishing class 1.

Other types of bag filters, with

efficiency classes F5, F6, F7, F8, or F9

are available upon request.

Hygroscopic sorption enthalpy

heat recovery wheel

Air-to-air, rotary hygroscopic

sorption enthalpy heat recovery

unit, with honeycomb wheel in

hygroscopic aluminum, can be

provided with removable sections,

or single body wheel, and fixed or

variable rotation speed.

Heat exchange coil

Bundle-type heat exchange coils,

operating with cold or hot water, and

with copper pipes and fins. Stainless

steel AISI 304 or AISI 316 frame.

Copper manifolds with gas-threaded

taps, fitted with air vent and water

drainage valves. All coils have been

tested to a pressure of 20 bar.

Droplet separator

Multi-blade droplet separator,

with AISI 304 or AISI 316 stainless

steel frame and flame-resistant

polypropylene fins B2-DIN4102.

Industrial fans

Double intake fans are used, fitted

with backward inclined, airfoil or flat

plate blades.

The volute and the impeller are of

heavy carbon steel construction,

protected by an epoxy coating.

Bearings and chocks are fitted with

greasing nipples.

Electric motors

Three-phase asynchronous motors,

made by UNEL-MEC, suitable for

operation in tropical environments,

with cast iron or epoxy coated

aluminum casing. Insulation class F

and protection IP55.

Motors of varying polarities are

available as required, with 380V, 440V,

690V – 3 Phase - 60 Hz power supply.

Motor/fan frame

The base support frame of the motor/

fan assembly is a galvanized carbon

steel fabrication, and is isolated from

the structure of the unit by special

rubber suspensions.

20 | 21