Thermostatic mixing valves ECOSAN are indispensables for saving water and energy.

Their use is provided by the law on energy savings which limits to 48°C the temperature of distribution of sanitary water. In many Countries the use of thermo-

static mixing valve is considered indispensable also for the prevention of “Legionella pneumophila”. In plants with the accumulation of hot sanitary water to avoid

the risk of developing this dangerous microorganism, the temperature of the water in the tank should not drop below 60°C-65°C. The water at this temperature

can not be used directly and so it is indispensable the installation of a thermostatic mixing valve to reduce and maintain constant the water’s temperature that

is distributed.

ECOSAN operating characteristics and safety

The constant temperature of water is obtained by the movement of a “distribution box” that regulates the permanence of the quantity of hot and cold water,

each change of temperature is corrected almost instantaneously, by a thermostatic element of wax and copper powder. To avoid the danger of burns, a

device blocks the supply of hot water if suddenly is missing the supply of cold water.

Diameter to be used

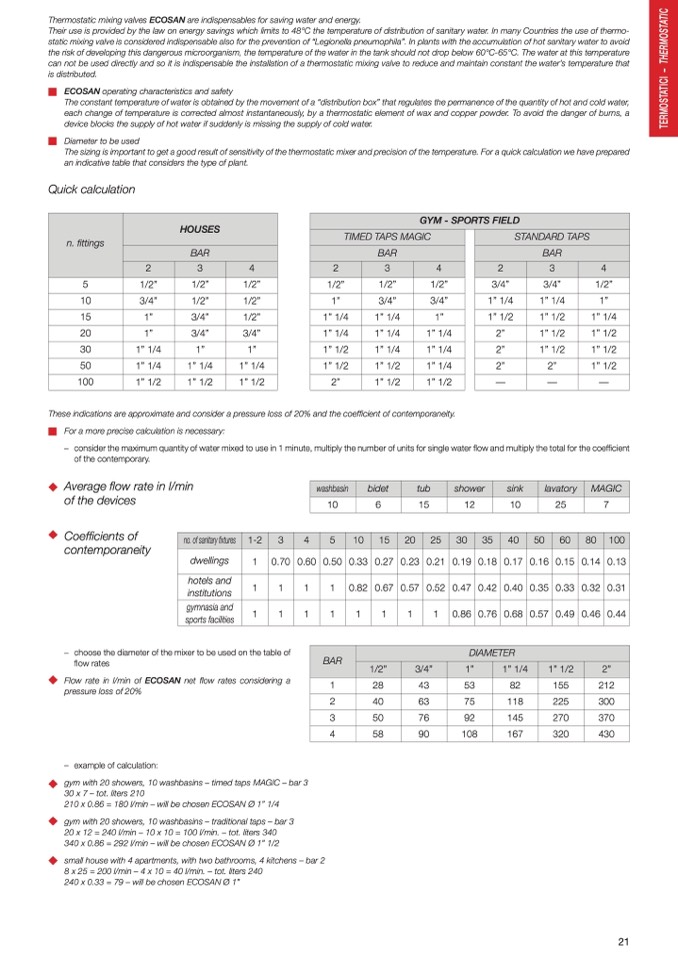

The sizing is important to get a good result of sensitivity of the thermostatic mixer and precision of the temperature. For a quick calculation we have prepared

an indicative table that considers the type of plant.

Quick calculation

n. fittings

HOUSES

BAR

2

3

4

5

1/2”

1/2”

1/2”

10

3/4”

1/2”

1/2”

15

1”

3/4”

1/2”

20

1”

3/4”

3/4”

30

1” 1/4

1”

1”

50

1” 1/4

1” 1/4

1” 1/4

100

1” 1/2

1” 1/2

1” 1/2

2

1/2”

1”

1” 1/4

1” 1/4

1” 1/2

1” 1/2

2”

TIMED TAPS MAGIC

3

1/2”

3/4”

1” 1/4

1” 1/4

1” 1/4

1” 1/2

1” 1/2

GYM - SPORTS FIELD

4

1/2”

3/4”

1”

1” 1/4

1” 1/4

1” 1/4

1” 1/2

2

3/4”

1” 1/4

1” 1/2

2”

2”

2”

—

STANDARD TAPS

BAR

BAR

3

3/4”

1” 1/4

1” 1/2

1” 1/2

1” 1/2

2”

—

4

1/2”

1”

1” 1/4

1” 1/2

1” 1/2

1” 1/2

—

These indications are approximate and consider a pressure loss of 20% and the coefficient of contemporaneity.

For a more precise calculation is necessary:

– consider the maximum quantity of water mixed to use in 1 minute, multiply the number of units for single water flow and multiply the total for the coefficient

of the contemporary.

Average flow rate in l/min

of the devices

Coefficients of

contemporaneity

– choose the diameter of the mixer to be used on the table of

flow rates

Flow rate in l/min of ECOSAN net flow rates considering a

pressure loss of 20%

– example of calculation:

gym with 20 showers, 10 washbasins – timed taps MAGIC – bar 3

30 x 7 – tot. liters 210

210 x 0.86 = 180 l/min – will be chosen ECOSAN Ø 1” 1/4

gym with 20 showers, 10 washbasins – traditional taps – bar 3

20 x 12 = 240 l/min – 10 x 10 = 100 l/min. – tot. liters 340

340 x 0.86 = 292 l/min – will be chosen ECOSAN Ø 1” 1/2

small house with 4 apartments, with two bathrooms, 4 kitchens – bar 2

8 x 25 = 200 l/min – 4 x 10 = 40 l/min. – tot. liters 240

240 x 0.33 = 79 – will be chosen ECOSAN Ø 1”

washbasin

bidet

tub

shower

sink

lavatory

MAGIC

10

6

15

12

10

25

7

no. of sanitary fixtures

1-2

3

4

5

10

15

20

25

30

35

40

50

60

80

100

dwellings

1

0.70

0.60

0.50

0.33

0.27

0.23

0.21

0.19

0.18

0.17

0.16

0.15

0.14

0.13

hotels and

institutions

1

1

1

1

0.82

0.67

0.57

0.52

0.47

0.42

0.40

0.35

0.33

0.32

0.31

gymnasia and

sports facilities

1

1

1

1

1

1

1

1

0.86

0.76

0.68

0.57

0.49

0.46

0.44

BAR

DIAMETER

1/2”

3/4”

1”

1” 1/4

1” 1/2

2”

1

28

43

53

82

155

212

2

40

63

75

118

225

300

3

50

76

92

145

270

370

4

58

90

108

167

320

430

21

T

E

R

M

O

S

T

A

T

I

C

I

–

T

H

E

R

M

O

S

T

A

T

I

C