TECHNOLOGY / JIKA SANITARY CERAMICS /

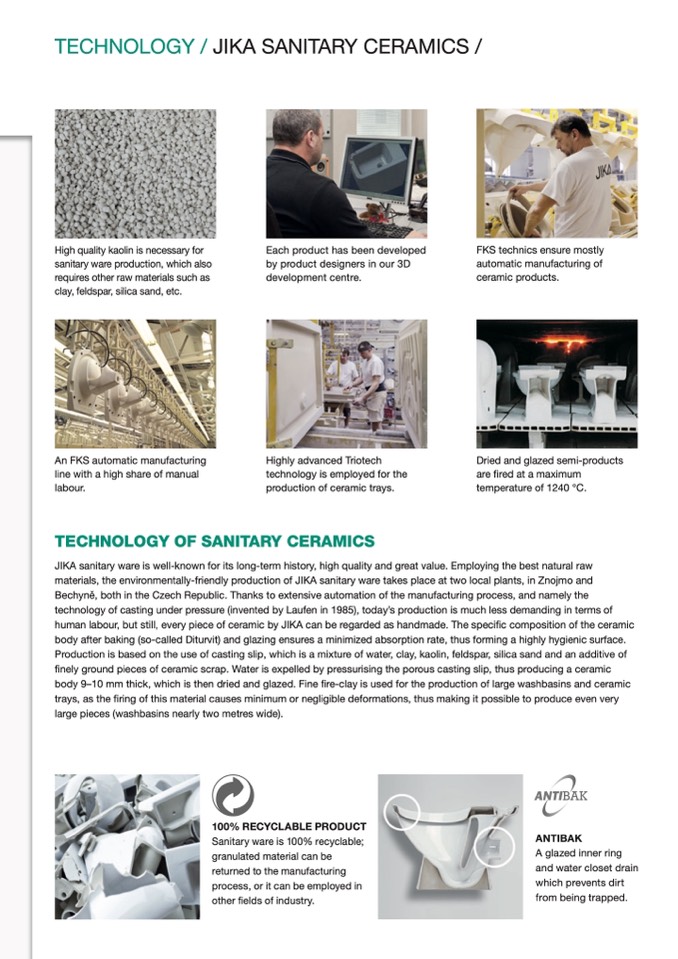

High quality kaolin is necessary for

sanitary ware production, which also

requires other raw materials such as

clay, feldspar, silica sand, etc.

Each product has been developed

by product designers in our 3D

development centre.

FKS technics ensure mostly

automatic manufacturing of

ceramic products.

An FKS automatic manufacturing

line with a high share of manual

labour.

Highly advanced Triotech

technology is employed for the

production of ceramic trays.

Dried and glazed semi-products

are fired at a maximum

temperature of 1240 °C.

TECHNOLOGY OF SANITARY CERAMICS

JIKA sanitary ware is well-known for its long-term history, high quality and great value. Employing the best natural raw

materials, the environmentally-friendly production of JIKA sanitary ware takes place at two local plants, in Znojmo and

Bechyně, both in the Czech Republic. Thanks to extensive automation of the manufacturing process, and namely the

technology of casting under pressure (invented by Laufen in 1985), today’s production is much less demanding in terms of

human labour, but still, every piece of ceramic by JIKA can be regarded as handmade. The specific composition of the ceramic

body after baking (so-called Diturvit) and glazing ensures a minimized absorption rate, thus forming a highly hygienic surface.

Production is based on the use of casting slip, which is a mixture of water, clay, kaolin, feldspar, silica sand and an additive of

finely ground pieces of ceramic scrap. Water is expelled by pressurising the porous casting slip, thus producing a ceramic

body 9–10 mm thick, which is then dried and glazed. Fine fire-clay is used for the production of large washbasins and ceramic

trays, as the firing of this material causes minimum or negligible deformations, thus making it possible to produce even very

large pieces (washbasins nearly two metres wide).

100% RECYCLABLE PRODUCT

Sanitary ware is 100% recyclable;

granulated material can be

returned to the manufacturing

process, or it can be employed in

other fields of industry.

ANTIBAK

A glazed inner ring

and water closet drain

which prevents dirt

from being trapped.