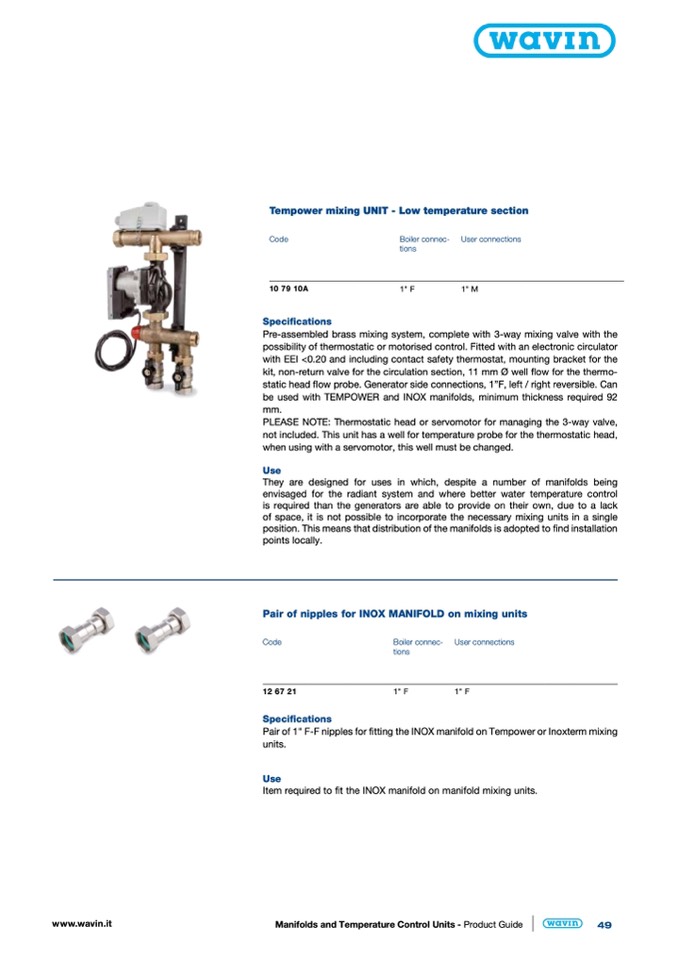

Tempower mixing UNIT - Low temperature section

Code

Boiler connec- User connections

tions

10 79 10A

1" F

1" M

Specifications

Pre-assembled brass mixing system, complete with 3-way mixing valve with the

possibility of thermostatic or motorised control. Fitted with an electronic circulator

with EEI <0.20 and including contact safety thermostat, mounting bracket for the

kit, non-return valve for the circulation section, 11 mm Ø well flow for the thermo-

static head flow probe. Generator side connections, 1”F, left / right reversible. Can

be used with TEMPOWER and INOX manifolds, minimum thickness required 92

mm.

PLEASE NOTE: Thermostatic head or servomotor for managing the 3-way valve,

not included. This unit has a well for temperature probe for the thermostatic head,

when using with a servomotor, this well must be changed.

Use

They are designed for uses in which, despite a number of manifolds being

envisaged for the radiant system and where better water temperature control

is required than the generators are able to provide on their own, due to a lack

of space, it is not possible to incorporate the necessary mixing units in a single

position. This means that distribution of the manifolds is adopted to find installation

points locally.

Pair of nipples for INOX MANIFOLD on mixing units

Code

Boiler connec- User connections

tions

12 67 21

1" F

1" F

Specifications

Pair of 1" F-F nipples for fitting the INOX manifold on Tempower or Inoxterm mixing

units.

Use

Item required to fit the INOX manifold on manifold mixing units.

www.wavin.it

Manifolds and Temperature Control Units - Product Guide

49