Technical details

FSR 4.105

FLEXWELL Safety Pipe

System description

Leak monitoring

The FLEXWELL Safety Pipe is permanently monitored using

pneumatic leak detection devices/leak detectors. These

regulate the monitoring pressure in the surveillance space and

register any changes of pressure which may occur.

The surveillance space prevents the uncontrolled escape of

the transport medium into the environment in the event of a

leakage. The surveillance space must be constructed in such

a way that the proper functioning and operating safety of the

leak detection system is ensured under all operating condi-

tions.

In the case of a leakage the alarm is given by acoustic and

optical signals.

Definition of a leak detection system

A “leak detection system” according to currently valid regu-

lations is a device which is capable of warning automatically

of leaks in the walls of double-walled piping transporting wa-

ter-hazardous (flammable and non-flammable) fluids under all

operating conditions. All equipment necessary for the detec-

tion of leaks is included under the term leak detection system/

leak detector.

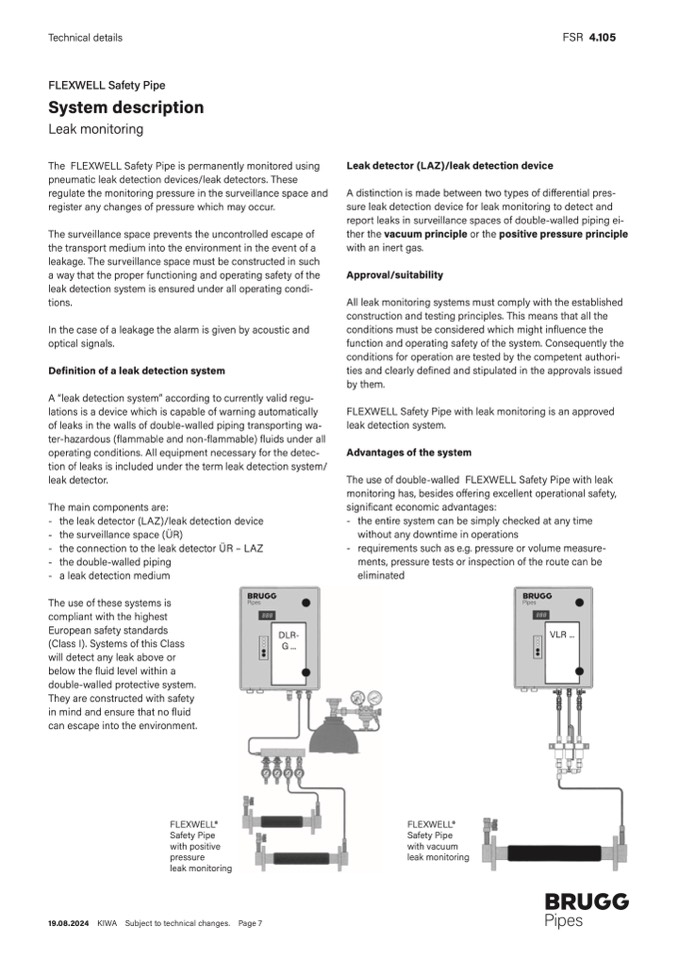

Leak detector (LAZ)/leak detection device

A distinction is made between two types of differential pres-

sure leak detection device for leak monitoring to detect and

report leaks in surveillance spaces of double-walled piping ei-

ther the vacuum principle or the positive pressure principle

with an inert gas.

Approval/suitability

All leak monitoring systems must comply with the established

construction and testing principles. This means that all the

conditions must be considered which might influence the

function and operating safety of the system. Consequently the

conditions for operation are tested by the competent authori-

ties and clearly defined and stipulated in the approvals issued

by them.

FLEXWELL Safety Pipe with leak monitoring is an approved

leak detection system.

Advantages of the system

The use of double-walled FLEXWELL Safety Pipe with leak

monitoring has, besides offering excellent operational safety,

significant economic advantages:

The main components are:

- the leak detector (LAZ)/leak detection device

- the surveillance space (ÜR)

- the connection to the leak detector ÜR – LAZ

- the double-walled piping

- a leak detection medium

The use of these systems is

compliant with the highest

European safety standards

(Class I). Systems of this Class

will detect any leak above or

below the fluid level within a

double-walled protective system.

They are constructed with safety

in mind and ensure that no fluid

can escape into the environment.

FLEXWELL®

Safety Pipe

with positive

pressure

leak monitoring

-

-

the entire system can be simply checked at any time

without any downtime in operations

requirements such as e.g. pressure or volume measure-

ments, pressure tests or inspection of the route can be

eliminated

19.08.2024

KIWA Subject to technical changes.

Page 7

DLR-

G ...

VLR ...

FLEXWELL®

Safety Pipe

with vacuum

leak monitoring