Technical details

FSR 4.100

FLEXWELL Safety Pipe

System description

Construction and function

The FLEXWELL Safety Pipe is a:

- double-walled, monitorable, flexible and factory produced

pipe system with all necessary quality tests

- approved for the transport of water-hazardous, flammable

or otherwise dangerous fluids

- recognized and approved leak detection system

5

1 2 3 4

- Dimensions:

- Pressure range:

- Temperature range:

- DIBt Approval Number:

Leak monitoring

DN12–DN150

–0,8 to 25 bar (temperature

range –30 °C to +60 °C

–0,8 to 10 bar (temperature

range –50 °C to +60 °C)

(max. dep. on fitting, FSR 4.2)

–30 °C to +60 °C (for PN 25 fittings)

–50 °C to +60 °C (for PN 10 fittings)

Z-38.4-253

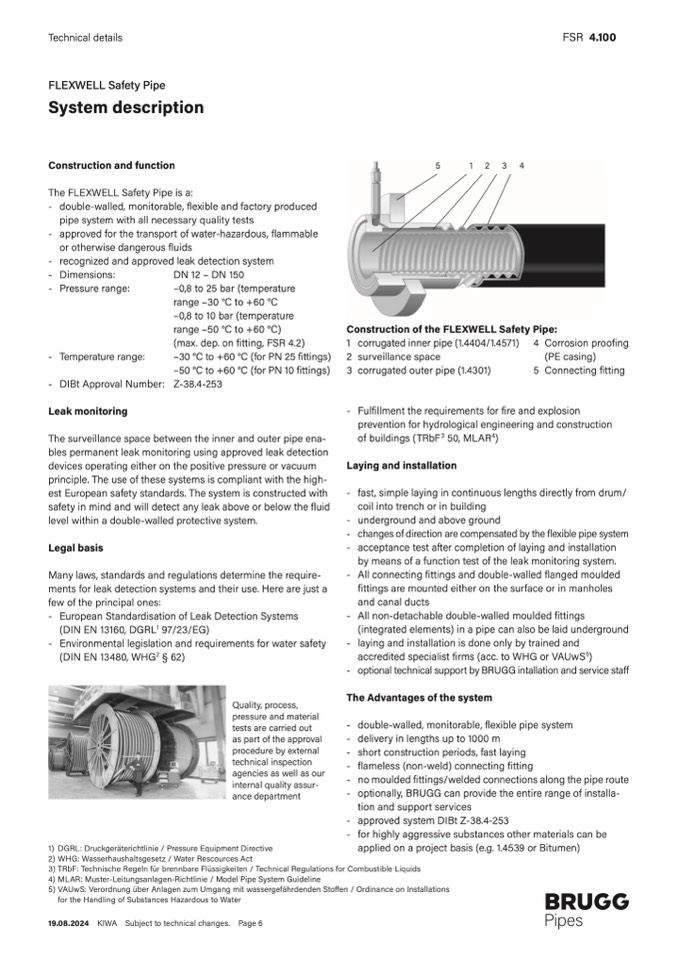

Construction of the FLEXWELL Safety Pipe:

The surveillance space between the inner and outer pipe ena-

bles permanent leak monitoring using approved leak detection

devices operating either on the positive pressure or vacuum

principle. The use of these systems is compliant with the high-

est European safety standards. The system is constructed with

safety in mind and will detect any leak above or below the fluid

level within a double-walled protective system.

Legal basis

Many laws, standards and regulations determine the require-

ments for leak detection systems and their use. Here are just a

few of the principal ones:

- Fulfillment the requirements for fire and explosion

prevention for hydrological engineering and construction

of buildings (TRbF

3

50, MLAR

4

)

Laying and installation

- fast, simple laying in continuous lengths directly from drum/

coil into trench or in building

- underground and above ground

- changes of direction are compensated by the flexible pipe system

- acceptance test after completion of laying and installation

by means of a function test of the leak monitoring system.

- All connecting fittings and double-walled flanged moulded

fittings are mounted either on the surface or in manholes

and canal ducts

- All non-detachable double-walled moulded fittings

(integrated elements) in a pipe can also be laid underground

- laying and installation is done only by trained and

accredited specialist firms (acc. to WHG or VAUwS

5

)

- optional technical support by BRUGG intallation and service staff

The Advantages of the system

- double-walled, monitorable, flexible pipe system

- delivery in lengths up to 1000 m

- short construction periods, fast laying

- flameless (non-weld) connecting fitting

- no moulded fittings/welded connections along the pipe route

- optionally, BRUGG can provide the entire range of installa-

tion and support services

- approved system DIBt Z-38.4-253

- for highly aggressive substances other materials can be

-

-

European Standardisation of Leak Detection Systems

(DIN EN 13160, DGRL

1

97/23/EG)

Environmental legislation and requirements for water safety

(DIN EN 13480, WHG

2

§ 62)

Quality, process,

pressure and material

tests are carried out

as part of the approval

procedure by external

technical inspection

agencies as well as our

internal quality assur-

ance department

DGRL: Druckgeräterichtlinie / Pressure Equipment Directive

WHG: Wasserhaushaltsgesetz / Water Rescources Act

TRbF: Technische Regeln für brennbare Flüssigkeiten / Technical Regulations for Combustible Liquids

MLAR: Muster-Leitungsanlagen-Richtlinie / Model Pipe System Guideline

VAUwS: Verordnung über Anlagen zum Umgang mit wassergefährdenden Stoffen / Ordinance on Installations

for the Handling of Substances Hazardous to Water

1 corrugated inner pipe (1.4404/1.4571)

2 surveillance space

3 corrugated outer pipe (1.4301)

4 Corrosion proofing

(PE casing)

5 Connecting fitting

1)

2)

3)

4)

5)

applied on a project basis (e.g. 1.4539 or Bitumen)

19.08.2024 KIWA Subject to technical changes. Page 6