Installation and mounting

only trained and qualified person must be permitted to perform work on gas regulators and safety devices.

Install the regulating train directly upstream of the gas-consuming devices.

Install the regulating train so that the direction arrows point towards the filter, safety shut-off valve, pressure regulator and

solenoid valves in the direction of gas flow.

Normally, the gas passage is horizontally. The installation of the regulating trains is independent of position due to the spring

loads. The device works therefore in any position.

If necessary, readjust the output pressure.

Position the pulse lines for SAV and pressure regulator so that you can monitor a steady output pressure (approx. 10 x DN).

Designed with 12 mm dia. steel pipe and cutting ring unions.

Take particular care that pulse lines are not damaged during mounting.

Connect the vent lines to the vent connections and route them outdoors.

Ensure that the sealing rings are inserted.

Ensure that the connection lines and the devices are free from contamination to avoid damages and operational faults.

Commissioning

slowly open the ball valve upstream of the regulating train and then the burner ball valve (if installed).

Observe the output pressure at the manometer and, if necessary, readjust at the load spring. Ensure that there is no zero

consumption, otherwise the closing pressure must also be measured.

The output pressure in the pressure regulator, the switch-off pressure in the SAV and the vent pressure in the SBV are set at

our factory to the values specified in the enclosed datasheet.

Output pressure adjustment

The output pressure Pa must be higher than the sum of resistances of all downstream fittings and gas-consuming devices.

If it is necessary to correct the output pressure, readjust the pressure regulator setting screw. Open the closing cover. Then

change the pressure to the desired value by turning the setting screw. Pressure will increase by turning clockwise.

This can be performed during operation since all gas-conveying chambers in the regulator are closed.

If the SAV close due to a operating fault at the pressure regulator, you can manually open the SAV after elim- inating the fault.

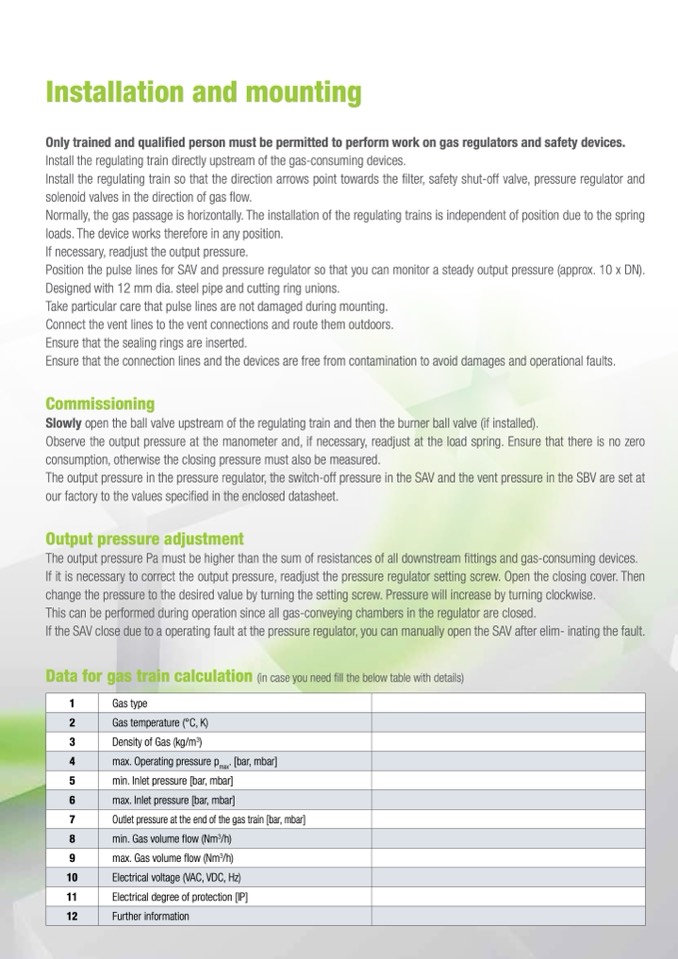

Data for gas train calculation

(in case you need fill the below table with details)

1

Gas type

2

Gas temperature (°C, K)

3

Density of Gas (kg/m

3

)

4

max. Operating pressure p

max

. [bar, mbar]

5

min. Inlet pressure [bar, mbar]

6

max. Inlet pressure [bar, mbar]

7

Outlet pressure at the end of the gas train [bar, mbar]

8

min. Gas volume flow (Nm

3

/h)

9

max. Gas volume flow (Nm

3

/h)

10

Electrical voltage (VAC, VDC, Hz)

11

Electrical degree of protection [IP]

12

Further information

9