Boiler house

Steam injectors

Local regulations may restrict the use of this product to below the conditions quoted.

In the interests of development and improvement of the product, we reserve the right to change the specification without notice.

© Copyright 2015

TI-P401-06

AB Issue 5

Description

Spirax Sarco steam distributors distribute low pressure flash steam

into atmospheric water tanks. They ensure rapid condensation of the

steam and efficient heating of the water. The hole configuration

provides a self-regulating control feature ensuring that holes

progressively come into use as the steam flowrate increases. An

internal stainless steel mesh ensures quiet operation.

Principal features:

-

Simple installation - no special supports required.

-

Compact, lightweight and strong.

-

Stainless steel for long life.

-

Eliminates waterhammer.

-

Quiet operation.

Application - Boiler blowdown heat recovery

Steam distributors are ideal for supplementing the heating of boiler

feedwater tanks using flash steam. When used in conjunction with

a flash vessel, as part of a boiler blowdown heat recovery system,

flash steam recovery is simple, of low capital cost and is maintenance

free. Additionally, the flash steam is condensed to pure water reducing

the amount of make-up water and chemical treatment required.

Generally for sizing purposes use a differential pressure of 0.4 bar.

Steam distributors are not recommended for condensate recovery

or live steam injection duties, as they may be damaged by

waterhammer.

Available types

SD40S, SD50S and SD80S screwed BSP (BS 21 parallel) or NPT.

SD80, SD100 and SD150 flanged to suit EN 1092 PN16 or

ASME Class 150.

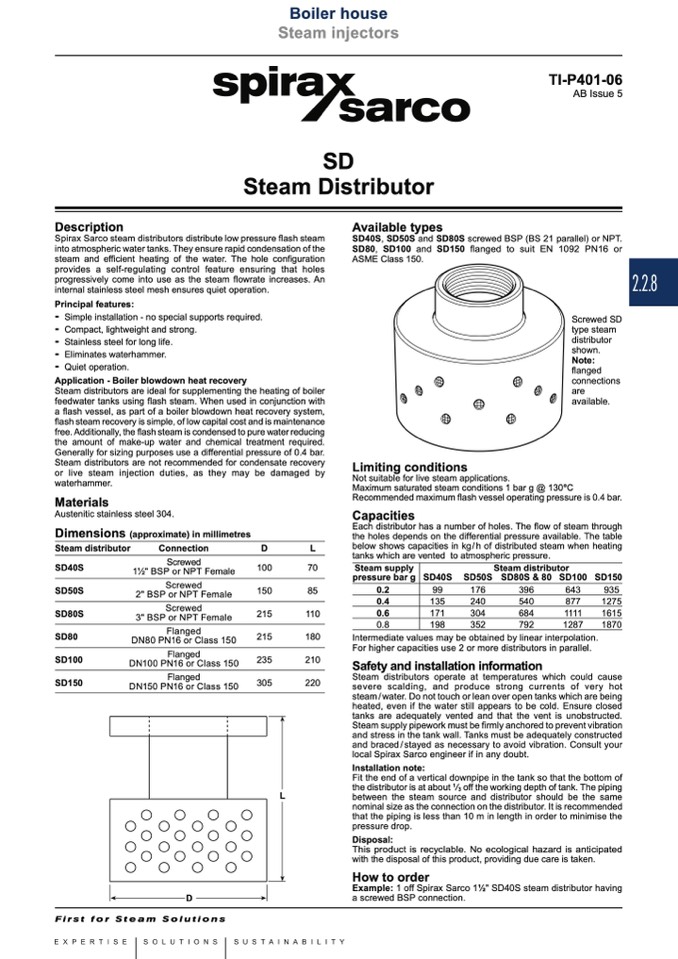

Screwed SD

type steam

distributor

shown.

Note:

flanged

connections

are

available.

Limiting conditions

Not suitable for live steam applications.

Maximum saturated steam conditions 1 bar g @ 130°C

Recommended maximum flash vessel operating pressure is 0.4 bar.

Capacities

Each distributor has a number of holes. The flow of steam through

the holes depends on the differential pressure available. The table

below shows capacities in kg/h of distributed steam when heating

tanks which are vented to atmospheric pressure.

2.2.8

SD

Steam Distributor

Materials

Austenitic stainless steel 304.

Dimensions (approximate) in millimetres

Steam distributor

SD40S

SD50S

SD80S

SD80

SD100

SD150

Connection

Screwed

11⁄2" BSP or NPT Female

Screwed

2" BSP or NPT Female

Screwed

3" BSP or NPT Female

Flanged

DN80 PN16 or Class 150

Flanged

DN100 PN16 or Class 150

Flanged

DN150 PN16 or Class 150

D

100

150

215

215

235

305

L

70

85

110

180

210

220

Steam supply

pressure bar g SD40S

0.2

99

0.4

135

0.6

171

0.8

198

Steam distributor

SD50S SD80S & 80 SD100

176

396

643

240

540

877

304

684

1111

352

792

1287

SD150

935

1275

1615

1870

Intermediate values may be obtained by linear interpolation.

For higher capacities use 2 or more distributors in parallel.

Safety and installation information

L

Steam distributors operate at temperatures which could cause

severe scalding, and produce strong currents of very hot

steam / water. Do not touch or lean over open tanks which are being

heated, even if the water still appears to be cold. Ensure closed

tanks are adequately vented and that the vent is unobstructed.

Steam supply pipework must be firmly anchored to prevent vibration

and stress in the tank wall. Tanks must be adequately constructed

and braced/stayed as necessary to avoid vibration. Consult your

local Spirax Sarco engineer if in any doubt.

Installation note:

Fit the end of a vertical downpipe in the tank so that the bottom of

the distributor is at about

1

/

3

off the working depth of tank. The piping

between the steam source and distributor should be the same

nominal size as the connection on the distributor. It is recommended

that the piping is less than 10 m in length in order to minimise the

pressure drop.

Disposal:

This product is recyclable. No ecological hazard is anticipated

with the disposal of this product, providing due care is taken.

How to order

Example: 1 off Spirax Sarco 11⁄2" SD40S steam distributor having

a screwed BSP connection.

D