Boiler house

Feedtank ancillaries

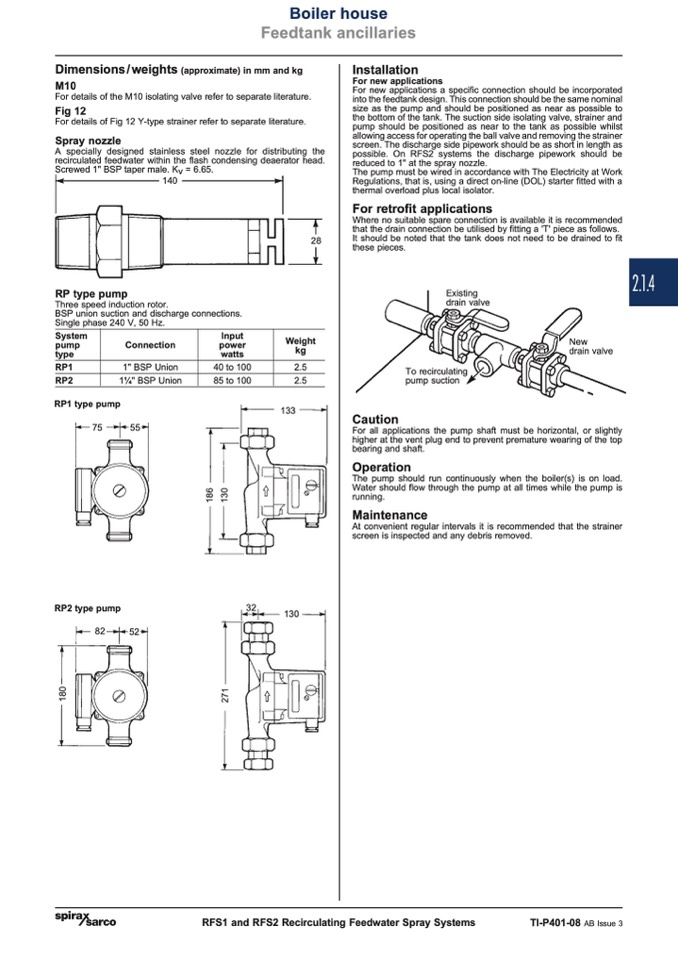

Dimensions / weights (approximate) in mm and kg

M10

For details of the M10 isolating valve refer to separate literature.

Fig 12

For details of Fig 12 Y-type strainer refer to separate literature.

Spray nozzle

Installation

For new applications

For new applications a specific connection should be incorporated

into the feedtank design. This connection should be the same nominal

size as the pump and should be positioned as near as possible to

the bottom of the tank. The suction side isolating valve, strainer and

pump should be positioned as near to the tank as possible whilst

allowing access for operating the ball valve and removing the strainer

screen. The discharge side pipework should be as short in length as

possible. On RFS2 systems the discharge pipework should be

reduced to 1" at the spray nozzle.

The pump must be wired in accordance with The Electricity at Work

Regulations, that is, using a direct on-line (DOL) starter fitted with a

thermal overload plus local isolator.

For retrofit applications

Where no suitable spare connection is available it is recommended

that the drain connection be utilised by fitting a 'T' piece as follows.

It should be noted that the tank does not need to be drained to fit

these pieces.

A specially designed stainless steel nozzle for distributing the

recirculated feedwater within the flash condensing deaerator head.

Screwed 1" BSP taper male. K

140

RP type pump

v = 6.65.

Three speed induction rotor.

BSP union suction and discharge connections.

Single phase 240 V, 50 Hz.

System

pump

type

RP1

RP2

RP1 type pump

75

28

Weight

kg

2.5

2.5

133

Existing

drain valve

To recirculating

pump suction

New

drain valve

Connection

Input

power

watts

1" BSP Union

40 to 100

11⁄4" BSP Union

85 to 100

RP2 type pump

82

32

130

55

Caution

52

For all applications the pump shaft must be horizontal, or slightly

higher at the vent plug end to prevent premature wearing of the top

bearing and shaft.

Operation

The pump should run continuously when the boiler(s) is on load.

Water should flow through the pump at all times while the pump is

running.

Maintenance

At convenient regular intervals it is recommended that the strainer

screen is inspected and any debris removed.

RFS1 and RFS2 Recirculating Feedwater Spray Systems

TI-P401-08 AB Issue 3

2.1.4

1

8

0

1

8

6

2

7

1

1

3

0