Transparency in detail

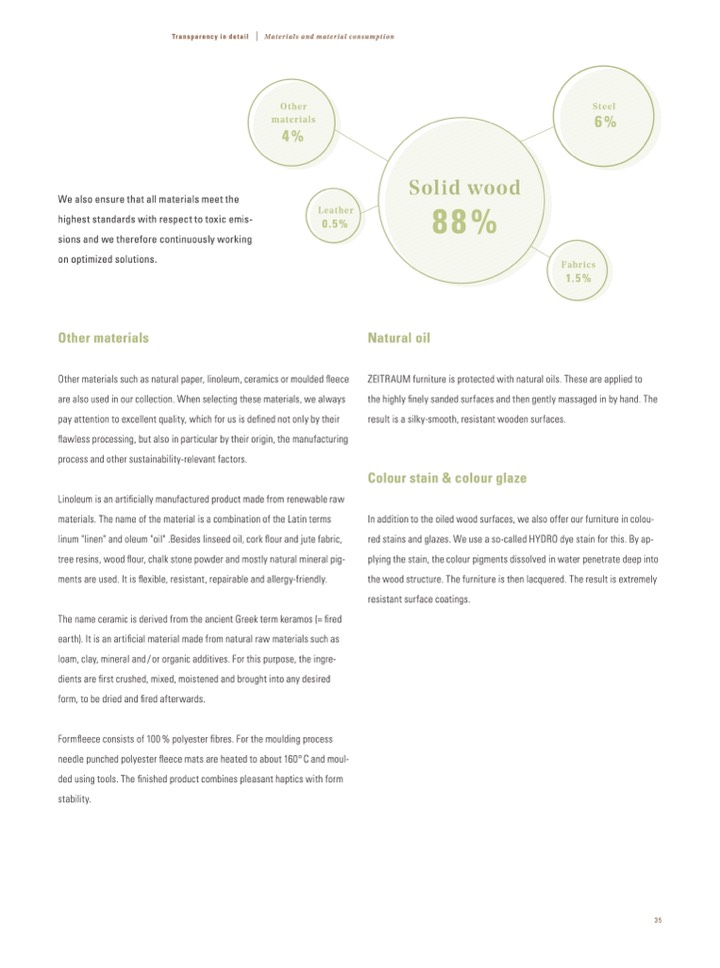

Materials and material consumption

We also ensure that all materials meet the

highest standards with respect to toxic emis-

sions and we therefore continuously working

on optimized solutions.

Other materials

Other

materials

4%

0.5%

Solid wood

88%

Steel

6%

Fabrics

1.5%

Leather

Other materials such as natural paper, linoleum, ceramics or moulded fleece

are also used in our collection. When selecting these materials, we always

pay attention to excellent quality, which for us is defined not only by their

flawless processing, but also in particular by their origin, the manufacturing

process and other sustainability-relevant factors.

Linoleum is an artificially manufactured product made from renewable raw

materials. The name of the material is a combination of the Latin terms

linum "linen" and oleum "oil" .Besides linseed oil, cork

flour and jute fabric,

tree resins, wood flour, chalk stone powder and mostly natural mineral pig-

ments are used. It is flexible, resistant, repairable and allergy-friendly.

The name ceramic is derived from the ancient Greek term keramos (= fired

earth). It is an artificial material made from natural raw materials such as

loam, clay, mineral and / or organic additives. For this purpose, the ingre-

dients are first crushed, mixed, moistened and brought into any desired

form, to be dried and fired afterwards.

Formfleece consists of 100 % polyester fibres. For the moulding process

needle punched polyester fleece mats are heated to about 160° C and moul-

ded using tools. The finished product combines pleasant haptics with form

stability.

ZEITRAUM furniture is protected with natural oils. These are applied to

the highly finely sanded surfaces and then gently massaged in by hand. The

result is a silky-smooth, resistant wooden surfaces.

Colour stain & colour glaze

In addition to the oiled wood surfaces, we also offer our furniture in colou-

red stains and glazes. We use a so-called HYDRO dye stain for this. By ap-

plying the stain, the colour pigments dissolved in water penetrate deep into

the wood structure. The furniture is then lacquered. The result is extremely

resistant surface coatings.

Natural oil

35