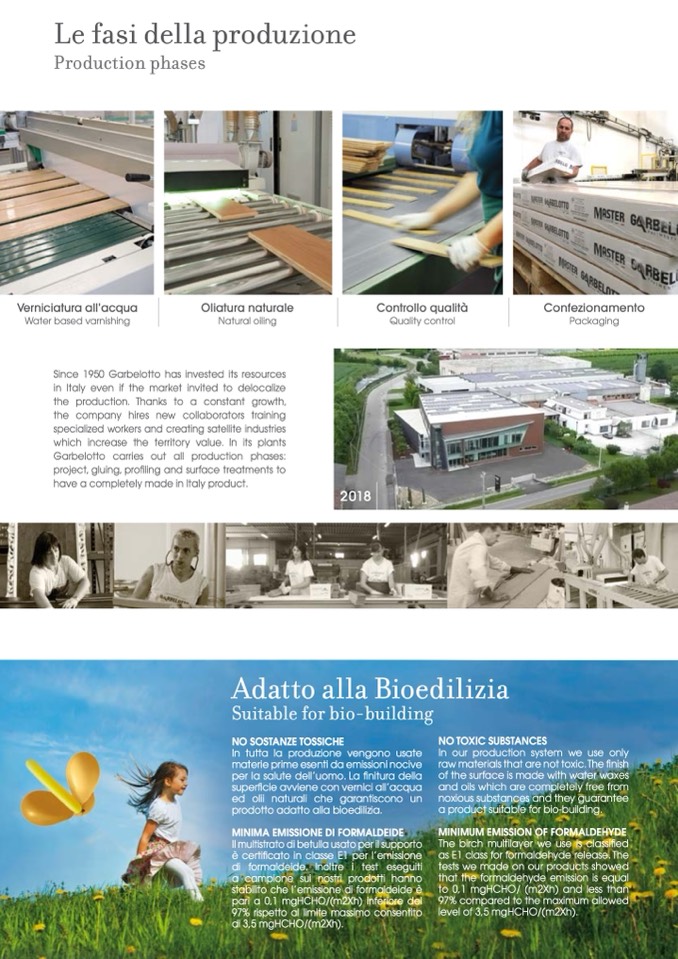

Le fasi della produzione

Production phases

Verniciatura all’acqua

Oliatura naturale

Water based varnishing

natural oiling

since 1950 garbelotto has invested its resources

in Italy even if the market invited to delocalize

the production. Thanks to a constant growth,

the company hires new collaborators training

specialized workers and creating satellite industries

which increase the territory value. In its plants

garbelotto carries out all production phases:

project, gluing, profiling and surface treatments to

have a completely made in Italy product.

Controllo qualità

quality control

Confezionamento

packaging

2018

Adatto alla Bioedilizia

Suitable for bio-building

NO SOSTANZE TOSSICHE

In tutta la produzione vengono usate

materie prime esenti da emissioni nocive

per la salute dell’uomo. la fifinitura della

superfificie avviene con vernici all’acqua

ed olii naturali che garantiscono un

prodotto adatto alla bioedilizia.

MINIMA EMISSIONE DI FORMALDEIDE

Il multistrato di betulla usato per il supporto

è certifificato in classe E1 per l’emissione

di formaldeide. Inoltre i test eseguiti

a campione sui nostri prodotti hanno

stabilito che l’emissione di formaldeide è

pari a 0,1 mgHCHo/(m2xh) inferiore del

97% rispetto al limite massimo consentito

di 3,5 mgHCHo/(m2xh).

NO TOXIC SUBSTANCES

In our production system we use only

raw materials that are not toxic.The fifinish

of the surface is made with water waxes

and oils which are completely free from

noxious substances and they guarantee

a product suitable for bio-building.

MINIMUM EMISSION OF FORMALDEHYDE

The birch multilayer we use is classifified

as E1 class for formaldehyde release. The

tests we made on our products showed

that the formaldehyde emission is equal

to 0,1 mgHCHO/ (m2Xh) and less than

97% compared to the maximum allowed

level of 3,5 mgHCHO/(m2Xh).