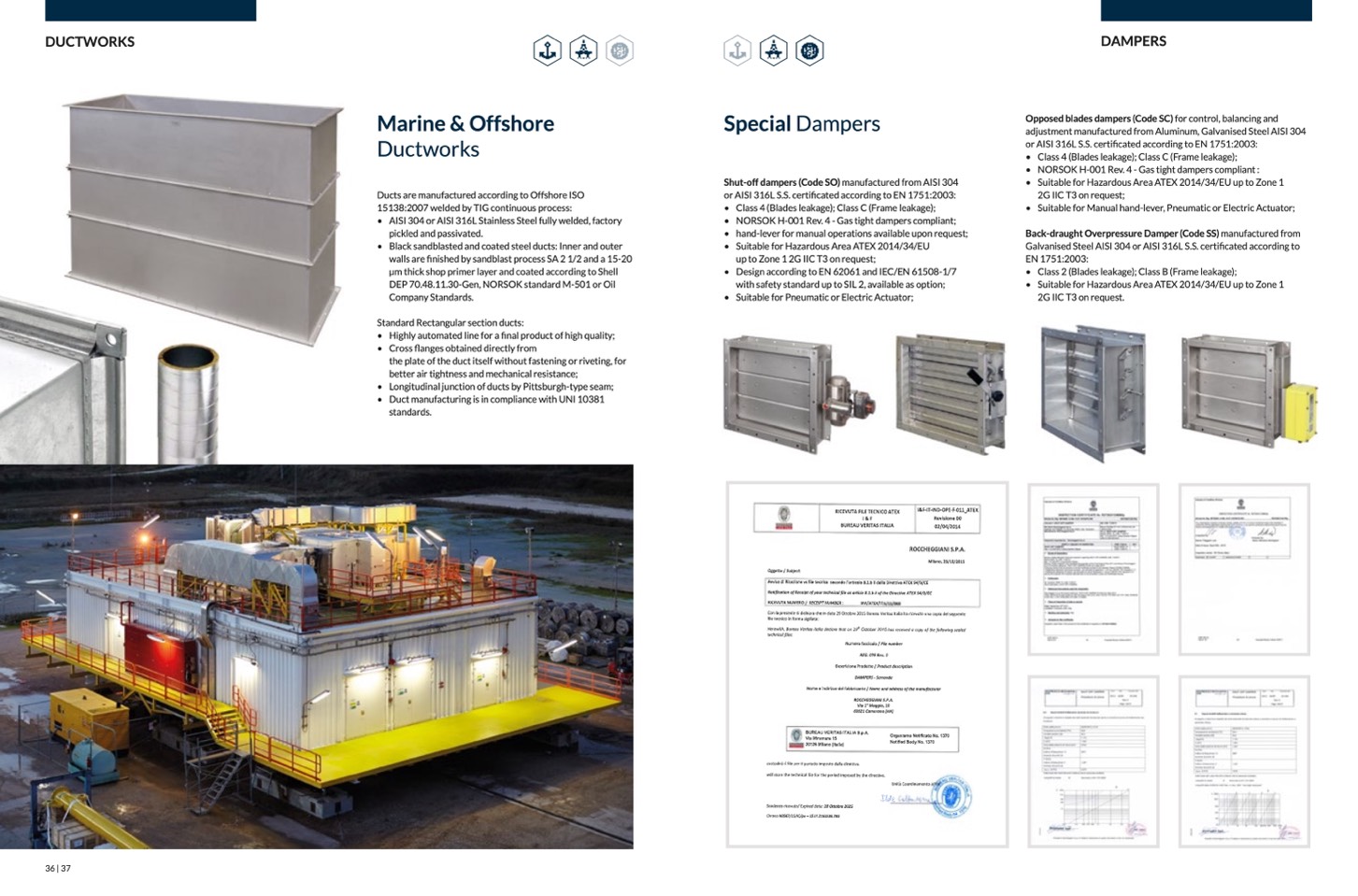

DUCTWORKS

DAMPERS

Marine & Offshore

Ductworks

Ducts are manufactured according to Offshore ISO

15138:2007 welded by TIG continuous process:

• AISI 304 or AISI 316L Stainless Steel fully welded, factory

pickled and passivated.

• Black sandblasted and coated steel ducts: Inner and outer

walls are finished by sandblast process SA 2 1/2 and a 15-20

μm thick shop primer layer and coated according to Shell

DEP 70.48.11.30-Gen, NORSOK standard M-501 or Oil

Company Standards.

Standard Rectangular section ducts:

• Highlyautomatedlineforafinalproductofhighquality;

• Crossflangesobtaineddirectlyfrom

the plate of the duct itself without fastening or riveting, for

better air tightness and mechanical resistance;

• LongitudinaljunctionofductsbyPittsburgh-typeseam;

• DuctmanufacturingisincompliancewithUNI10381

standards.

Special Dampers

Shut-off dampers (Code SO) manufactured from AISI 304

or AISI 316L S.S. certificated according to EN 1751:2003:

• Class 4 (Blades leakage); Class C (Frame leakage);

• NORSOK H-001 Rev. 4 - Gas tight dampers compliant;

• hand-lever for manual operations available upon request;

• Suitable for Hazardous Area ATEX 2014/34/EU

up to Zone 1 2G IIC T3 on request;

• Design according to EN 62061 and IEC/EN 61508-1/7

with safety standard up to SIL 2, available as option;

• Suitable for Pneumatic or Electric Actuator;

Opposed blades dampers (Code SC) for control, balancing and

adjustment manufactured from Aluminum, Galvanised Steel AISI 304

or AISI 316L S.S. certificated according to EN 1751:2003:

• Class4(Bladesleakage);ClassC(Frameleakage);

• NORSOKH-001Rev.4-Gastightdamperscompliant:

• Suitable for Hazardous Area ATEX 2014/34/EU up to Zone 1

2G IIC T3 on request;

• Suitable for Manual hand-lever, Pneumatic or Electric Actuator;

Back-draught Overpressure Damper (Code SS) manufactured from

Galvanised Steel AISI 304 or AISI 316L S.S. certificated according to

EN 1751:2003:

• Class 2 (Blades leakage); Class B (Frame leakage);

• Suitable for Hazardous Area ATEX 2014/34/EU up to Zone 1

2G IIC T3 on request.

36 | 37