Rattan

PROCESSING & MANUFACTURING

According to the Indonesian people, rattan is hugging the

rainforest. This is meant both literally as rattan grows

like lianas around the trees but also figuratively speaking,

because the use of rattan help preserving the rainforest as

there is no rattan production without the rainforest.

80% of the world’s rattan resources grow in the Indonesian

rain forest. Rattan is fast growing and regenerates in the

span of 5-7 years. In nature, rattan absorbs CO2 and

produces up to 35% more oxygen than a tree. Rattan

comes in 600 different variants and from these 40 can be

used in the production of furniture. At Sika-Design we only

use the two best qualities called Tohiti and Manau.

Making rattan furniture is extensive work that requires

many skilled hands. The process already begins in the

rainforest where experienced harvesters assess which

lianas are mature enough to be cut down.

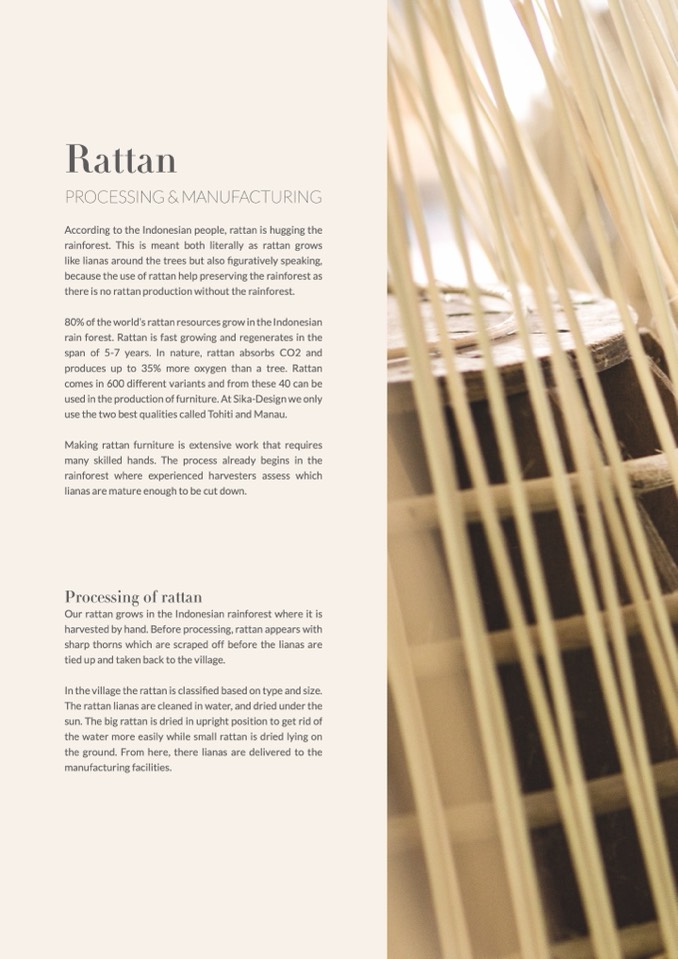

Processing of rattan

Our rattan grows in the Indonesian rainforest where it is

harvested by hand. Before processing, rattan appears with

sharp thorns which are scraped off before the lianas are

tied up and taken back to the village.

In the village the rattan is classified based on type and size.

The rattan lianas are cleaned in water, and dried under the

sun. The big rattan is dried in upright position to get rid of

the water more easily while small rattan is dried lying on

the ground. From here, there lianas are delivered to the

manufacturing facilities.