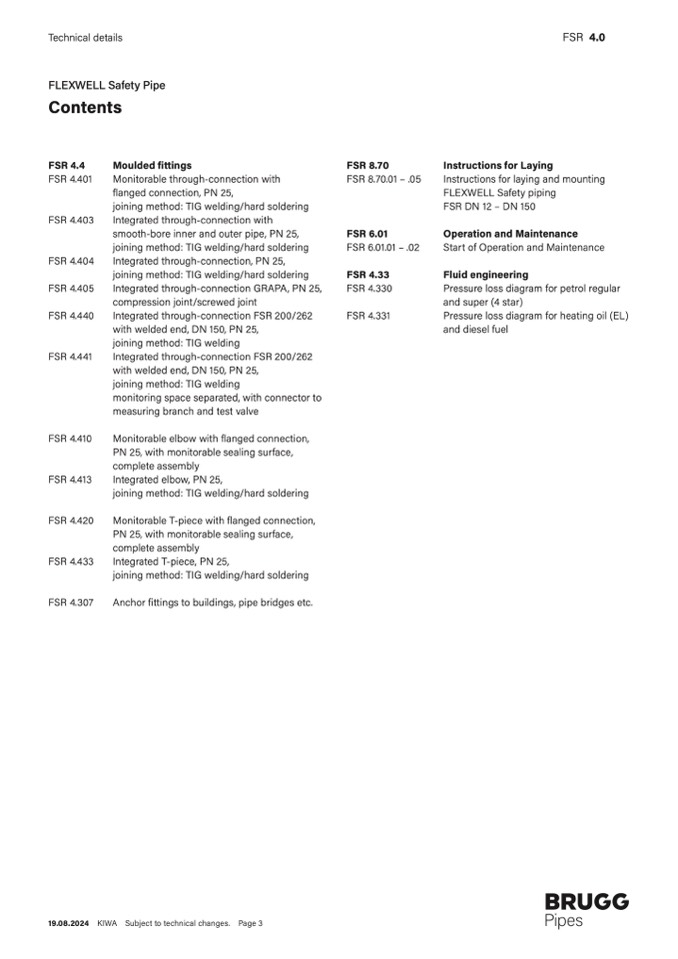

Technical details

FSR 4.0

FLEXWELL Safety Pipe

Contents

FSR 4.4

FSR 4.401

FSR 4.403

FSR 4.404

FSR 4.405

FSR 4.440

FSR 4.441

FSR 4.410

FSR 4.413

FSR 4.420

FSR 4.433

FSR 4.307

Moulded fittings

Monitorable through-connection with

flanged connection, PN 25,

joining method: TIG welding/hard soldering

Integrated through-connection with

smooth-bore inner and outer pipe, PN 25,

joining method: TIG welding/hard soldering

Integrated through-connection, PN 25,

joining method: TIG welding/hard soldering

Integrated through-connection GRAPA, PN 25,

compression joint/screwed joint

Integrated through-connection FSR 200/262

with welded end, DN 150, PN 25,

joining method: TIG welding

Integrated through-connection FSR 200/262

with welded end, DN 150, PN 25,

joining method: TIG welding

monitoring space separated, with connector to

measuring branch and test valve

Monitorable elbow with flanged connection,

PN 25, with monitorable sealing surface,

complete assembly

Integrated elbow, PN 25,

joining method: TIG welding/hard soldering

Monitorable T-piece with flanged connection,

PN 25, with monitorable sealing surface,

complete assembly

Integrated T-piece, PN 25,

joining method: TIG welding/hard soldering

Anchor fittings to buildings, pipe bridges etc.

FSR 8.70

FSR 8.70.01 – .05

FSR 6.01

FSR 6.01.01 – .02

FSR 4.33

FSR 4.330

FSR 4.331

Instructions for Laying

Instructions for laying and mounting

FLEXWELL Safety piping

FSR DN 12 – DN 150

Operation and Maintenance

Start of Operation and Maintenance

Fluid engineering

Pressure loss diagram for petrol regular

and super (4 star)

Pressure loss diagram for heating oil (EL)

and diesel fuel

19.08.2024

KIWA Subject to technical changes. Page 3