Technical details

FSR 4.224

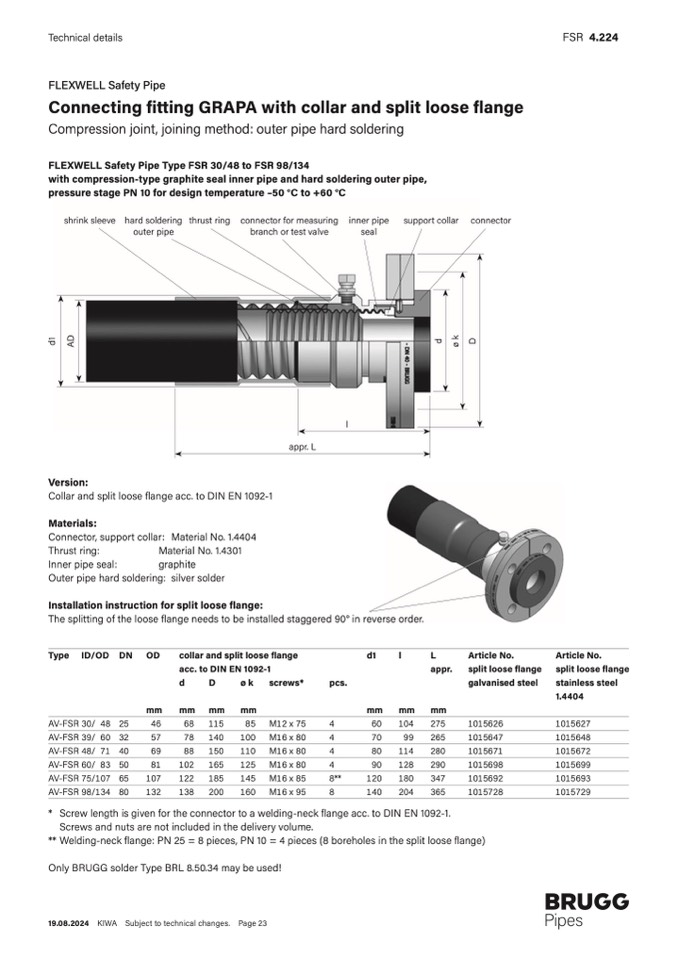

FLEXWELL Safety Pipe

Connecting fitting GRAPA with collar and split loose flange

Compression joint, joining method: outer pipe hard soldering

FLEXWELL Safety Pipe Type FSR 30/48 to FSR 98/134

with compression-type graphite seal inner pipe and hard soldering outer pipe,

pressure stage PN 10 for design temperature –50 °C to +60 °C

shrink sleeve hard soldering thrust ring

outer pipe

connector for measuring

branch or test valve

inner pipe

seal

support collar

connector

Version:

Collar and split loose flange acc. to DIN EN 1092-1

Materials:

Connector,supportcollar: MaterialNo.1.4404

Thrust ring:

Material No. 1.4301

Inner pipe seal:

graphite

Outer pipe hard soldering: silver solder

Installation instruction for split loose flange:

The splitting of the loose flange needs to be installed staggered 90° in reverse order.

Type ID/OD DN OD

collar and split loose flange

acc. to DIN EN 1092-1

d1

pcs.

l

L

appr.

Article No.

split loose flange

galvanised steel

1015626

1015647

1015671

1015698

1015692

1015728

Article No.

split loose flange

stainless steel

1.4404

1015627

1015648

1015672

1015699

1015693

1015729

AV-FSR 30/ 48 25

AV-FSR 39/ 60 32

AV-FSR 48/ 71 40

AV-FSR 60/ 83 50

AV-FSR 75/107 65

AV-FSR 98/134 80

4

60

4

70

4

80

4

90

8**

120

8

140

104

275

99

265

114

280

128

290

180

347

204

365

d

mm

mm

46

68

57

78

69

88

81

102

107

122

132

138

D

øk

mm

mm

115

85

140

100

150

110

165

125

185

145

200

160

screws*

M12x75

M16x80

M16x80

M16x80

M16x85

M16x95

mm

mm

mm

* Screw length is given for the connector to a welding-neck flange acc. to DIN EN 1092-1.

Screws and nuts are not included in the delivery volume.

** Welding-neck flange: PN 25 = 8 pieces, PN 10 = 4 pieces (8 boreholes in the split loose flange)

Only BRUGG solder Type BRL 8.50.34 may be used!

19.08.2024 KIWA Subject to technical changes. Page 23

l

appr. L

d

1

A

D

d

ø

k

D