Technical details

FSR 4.216

FLEXWELL Safety Pipe

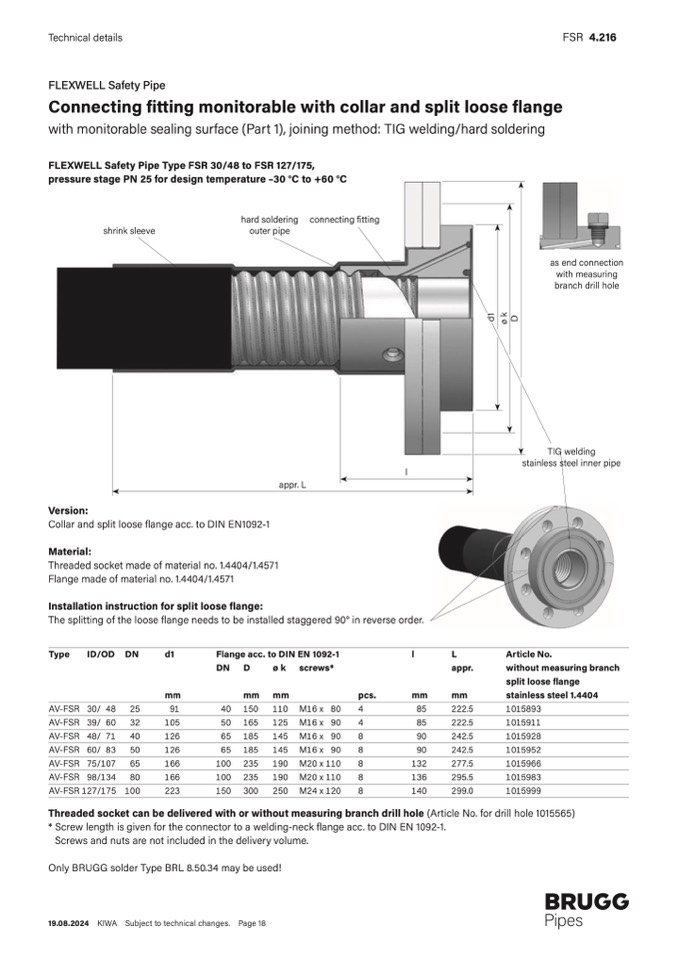

Connecting fitting monitorable with collar and split loose flange

with monitorable sealing surface (Part 1), joining method: TIG welding/hard soldering

FLEXWELL Safety Pipe Type FSR 30/48 to FSR 127/175,

pressure stage PN 25 for design temperature –30 °C to +60 °C

Version:

shrink sleeve

hard soldering

outer pipe

connecting fitting

appr. L

Collar and split loose flange acc. to DIN EN1092-1

Material:

Threaded socket made of material no. 1.4404/1.4571

Flange made of material no. 1.4404/1.4571

Installation instruction for split loose flange:

The splitting of the loose flange needs to be installed staggered 90° in reverse order.

Type

ID/OD DN

d1

mm

Flange acc. to DIN EN 1092-1

l

pcs.

mm

4

85

4

85

8

90

8

90

8

132

8

136

8

140

L

Article No.

appr.

without measuring branch

split loose flange

mm

stainless steel 1.4404

222.5

1015893

222.5

1015911

242.5

1015928

242.5

1015952

277.5

1015966

295.5

1015983

299.0

1015999

AV-FSR 30/ 48

AV-FSR 39/ 60

AV-FSR 48/ 71

AV-FSR 60/ 83

AV-FSR 75/107

AV-FSR 98/134

AV-FSR 127/175 100

223

DN D

øk

mm mm

40 150 110

50 165 125

65 185 145

65 185 145

100 235 190

100 235 190

150 300 250

screws*

M16 x 80

M16 x 90

M16 x 90

M16 x 90

M20 x 110

M20 x 110

M24 x 120

25 91

32 105

40 126

50 126

65 166

80 166

Threaded socket can be delivered with or without measuring branch drill hole (Article No. for drill hole 1015565)

* Screw length is given for the connector to a welding-neck flange acc. to DIN EN 1092-1.

Screws and nuts are not included in the delivery volume.

Only BRUGG solder Type BRL 8.50.34 may be used!

19.08.2024 KIWA Subject to technical changes. Page 18

l

TIG welding

stainless steel inner pipe

as end connection

with measuring

branch drill hole

d

1

ø

k

D