4.0 Jointing Instructions

4.1 Sizes 6 to 54 mm

All installations must be completed in line with local

regulations and by-laws governing the installation, and

all applicable health and safety practices must be

adhered to.

4.2 Minimum distances and insertion depths

Table 5:

4.3 Threaded joints for water applications

The use of a drinking water listed sealant or tape (e.g.

PTFE) is recommended for making joints on fittings

with taper male threads. For making joints with parallel

connector threads, a good quality washer should be used

to suit the particular application. Suitable drinking water

approved washers are supplied with Conex Compression

tap connector fittings and these should be used.

4.4 Connecting to plastic pipes

When joining soft copper tube to EN 1057-R220 or plastic

pipes to BS 7291, EN 15875 and EN 15876, it is essential

that an appropriate tube liner is also fitted. A Conex

Compression joint makes a metal to metal seal which

normally eliminates the need for jointing compounds and

sealants. On larger sizes, particularly 54 mm, it may be

necessary to use an additional WRAS approved sealant.

Jointing instructions, when using sealant, are available

from our technical department, technical@ibpgroup.com.

Table 6: Spanner size for compression nut

Tube

dimension

Minimum

distance

Minimum tube

length

Insertion

depth

A

L

E

mm

6

14

46

16

8

15

49

17

10

15

51

18

12

16

56

20

15

16

58

21

16

17

61

22

18

17

65

24

20

17

65

24

22

17

67

25

28

17

69

26

35

19

81

31

42

21

85

34

54

24

106

41

It is advisable to leave the fittings in the packaging prior

to final installation to protect them from contamination

and damage. As part of the installation process the space

required, and the minimum distance between Conex

Compression fittings, must be observed. For copper

tubes in a R220 annealed condition and plastic pipes

to BS 7291, EN 15875 and EN 15876 supporting liners

must be used.

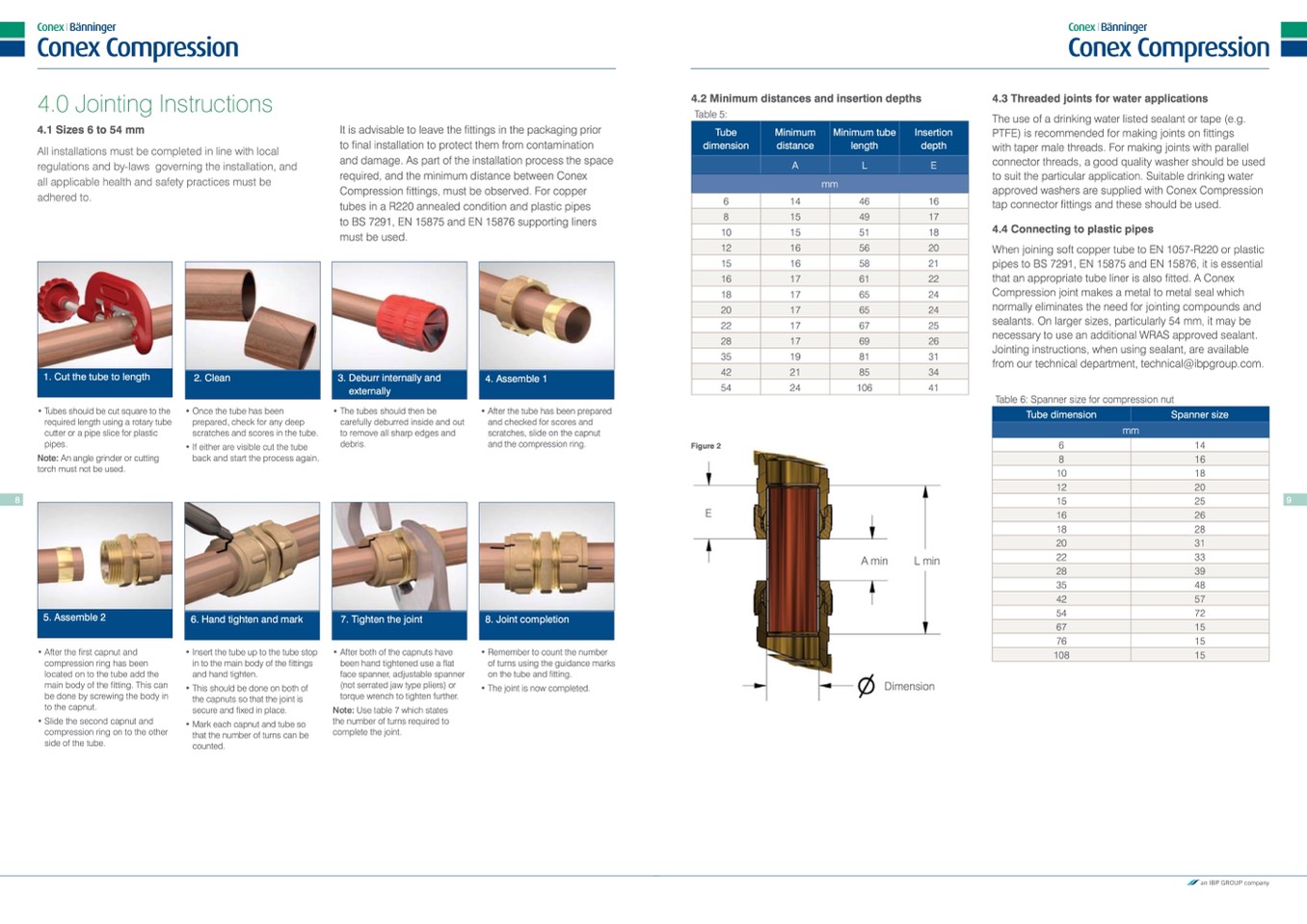

1. Cut the tube to length

2. Clean

3. Deburr internally and

externally

4. Assemble 1

Tube dimension

Spanner size

mm

6

14

8

16

10

18

12

20

15

25

16

26

18

28

20

31

22

33

28

39

35

48

42

57

54

72

67

15

76

15

108

15

• Tubes should be cut square to the

required length using a rotary tube

cutter or a pipe slice for plastic

pipes.

Note: An angle grinder or cutting

torch must not be used.

• Once the tube has been

prepared, check for any deep

scratches and scores in the tube.

• If either are visible cut the tube

back and start the process again.

• The tubes should then be

carefully deburred inside and out

to remove all sharp edges and

debris.

• After the tube has been prepared

and checked for scores and

scratches, slide on the capnut

and the compression ring.

Figure 2

8

9

5. Assemble 2

6. Hand tighten and mark

7. Tighten the joint

8. Joint completion

• After the first capnut and

compression ring has been

located on to the tube add the

main body of the fitting. This can

be done by screwing the body in

to the capnut.

• Slide the second capnut and

compression ring on to the other

side of the tube.

• Insert the tube up to the tube stop

in to the main body of the fittings

and hand tighten.

• This should be done on both of

the capnuts so that the joint is

secure and fixed in place.

• Mark each capnut and tube so

that the number of turns can be

counted.

• After both of the capnuts have

been hand tightened use a flat

face spanner, adjustable spanner

(not serrated jaw type pliers) or

torque wrench to tighten further.

Note: Use table 7 which states

the number of turns required to

complete the joint.

• Remember to count the number

of turns using the guidance marks

on the tube and fitting.

• The joint is now completed.

A min

L min

Dimension

E