Product Guide

TECHNICAL FEATURES

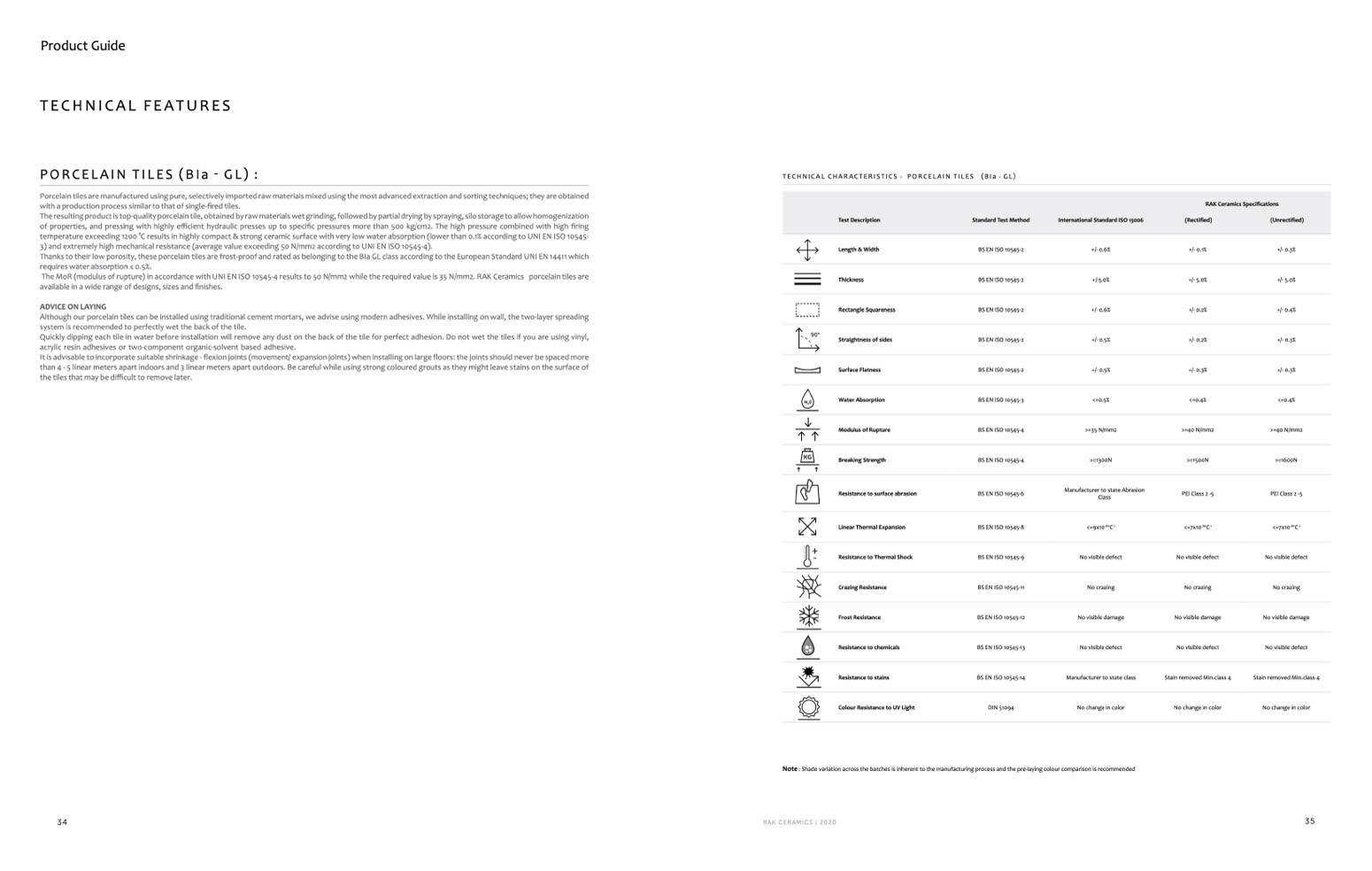

PORCELAIN TILES (BIa - GL) :

Porcelain tiles are manufactured using pure, selectively imported raw materials mixed using the most advanced extraction and sorting techniques; they are obtained

with a production process similar to that of single-fired tiles.

The resulting product is top-quality porcelain tile, obtained by raw materials wet grinding, followed by partial drying by spraying, silo storage to allow homogenization

of properties, and pressing with highly efficient hydraulic presses up to specific pressures more than 500 kg/cm2. The high pressure combined with high firing

temperature exceeding 1200 °C results in highly compact & strong ceramic surface with very low water absorption (lower than 0.1% according to UNI EN ISO 10545-

3) and extremely high mechanical resistance (average value exceeding 50 N/mm2 according to UNI EN ISO 10545-4).

Thanks to their low porosity, these porcelain tiles are frost-proof and rated as belonging to the BIa GL class according to the European Standard UNI EN 14411 which

requires water absorption ≤ 0.5%.

TECHNICAL CHARACTERISTICS - PORCELAIN TILES (BIa - GL)

Test Description

Standard Test Method

International Standard ISO 13006

RAK Ceramics

(Rectified)

Specifications

(Unrectified)

The MoR (modulus of rupture) in accordance with UNI EN ISO 10545-4 results to 50 N/mm2 while the required value is 35 N/mm2. RAK Ceramics

available in a wide range of designs, sizes and finishes.

ADVICE ON LAYING

porcelain tiles are

Length & Width

Thickness

Rectangle Squareness

Straightness of sides

Surface Flatness

Water Absorption

Modulus of Rupture

Breaking Strength

Resistance to surface abrasion

Linear Thermal Expansion

Resistance to Thermal Shock

Crazing Resistance

Frost Resistance

Resistance to chemicals

Resistance to stains

Colour Resistance to UV Light

BS EN ISO 10545-2

BS EN ISO 10545-2

BS EN ISO 10545-2

BS EN ISO 10545-2

BS EN ISO 10545-2

BS EN ISO 10545-3

BS EN ISO 10545-4

BS EN ISO 10545-4

BS EN ISO 10545-6

BS EN ISO 10545-8

BS EN ISO 10545-9

BS EN ISO 10545-11

BS EN ISO 10545-12

BS EN ISO 10545-13

BS EN ISO 10545-14

DIN 51094

+/- 0.6%

+/-5.0%

+/- 0.6%

+/- 0.5%

+/- 0.5%

<=0.5%

>=35 N/mm2

>=1300N

Manufacturer to state Abrasion

Class

<=9x10

-60

C

-1

No visible defect

No crazing

No visible damage

No visible defect

Manufacturer to state class

No change in color

+/- 0.1%

+/- 5.0%

+/- 0.2%

+/- 0.2%

+/- 0.3%

<=0.4%

>=40 N/mm2

>=1500N

PEI Class 2 -5

<=7x10

-60

C

-1

No visible defect

No crazing

No visible damage

No visible defect

Stain removed Min.class 4

No change in color

+/- 0.3%

+/- 5.0%

+/- 0.4%

+/- 0.3%

+/- 0.3%

<=0.4%

>=40 N/mm2

>=1600N

PEI Class 2 -5

<=7x10

-60

C

-1

No visible defect

No crazing

No visible damage

No visible defect

Stain removed Min.class 4

No change in color

Although our porcelain tiles can be installed using traditional cement mortars, we advise using modern adhesives. While installing on wall, the two-layer spreading

system is recommended to perfectly wet the back of the tile.

Quickly dipping each tile in water before installation will remove any dust on the back of the tile for perfect adhesion. Do not wet the tiles if you are using vinyl,

acrylic resin adhesives or two-component organic-solvent based adhesive.

It is advisable to incorporate suitable shrinkage - flexion joints (movement/ expansion joints) when installing on large floors: the joints should never be spaced more

than 4 - 5 linear meters apart indoors and 3 linear meters apart outdoors. Be careful while using strong coloured grouts as they might leave stains on the surface of

the tiles that may be difficult to remove later.

34

RAK CERAMICS | 2020

35

Note : Shade variation across the batches is inherent to the manufacturing process and the pre-laying colour comparison is recommended